INTRODUCTION

According to Igor Ansoff (as cited in David, 2008), all companies considered successful focus their efforts on optimizing the performance of one primary function; however, at present, the single-function approach must be replaced by a multifunctional approach, as the environment is becoming increasingly dynamic and complex. Therefore, it is essential to integrate the various management systems into a comprehensive organizational management system.

The International Organization for Standardization (ISO) defines a management system as the “set of interrelated or interacting elements of an organization to establish policies and objectives, and processes to achieve those objectives” (International Organization for Standardization [ISO], 2015a, p. 7). Organizational management systems can integrate various management systems, such as an occupational health and safety management system, an environmental management system, an anti-bribery management system, among others, as they share common elements. Under controlled conditions, the purpose of the management systems integration process is to design and implement a plan for the organization conforming to its context, objectives and level of maturity (Instituto Nacional de Defensa de la Competencia y de la Protección de la Propiedad Intelectual [INDECOPI], 2006). The PDCA cycle (plan-do-check-act) facilitates the integration process because it is an efficient and cost-effective method. Integration also enables the planning, provision of resources, formulation of objectives and evaluation of the overall performance of the organizations.

Compliance with applicable legal standards is a common element of management systems, which in turn supports the development of the components of the management system (Riaño-Casallas et al., 2016), in other words, the main changes in the management system occur due to amendments to the legal standards. It should be mentioned that before implementing any management system, usually, there is lack of knowledge in organizations regarding the applicable legal framework that governs them (Franco & Arias, 2018).

Another common element is risk management, which aims at adopting measures under a preventive approach that fosters an appropriate performance level of the management system (Clark et al., 2019), since the lack of such measures can result in environmental impacts, occupational accidents, occupational diseases, among other serious impacts.

Clark et al. (2019) and Jimenez and Nuñez (2014) concur that organizations must use tools to improve the performance of their operations to prevent or mitigate the impact on the environment and occupational health and safety. Similarly, Cabalé and Rodríguez (2020), Clark et al. (2019) and Estrada (2018) outline the benefits and advantages derived from the implementation of a management system based on the existing management systems already in place in the same organization.

As stated by Yamuca (2010), La Madrid (2008), Posada (2011) and Tapia (2013), several key elements must be considered for the implementation of management systems:

· Ensure the buy-in of the General Management in order to solve any problems that may arise during implementation.

· Stress the benefits to be obtained, preferably providing examples of direct application: waste management reduction, improved organization and cleanliness, motivated personnel, improved work environment, improved communication (internal and external), sharing of achievements, etc.

· Budget and provide resources for the implementation of improvements. Resources can be financial, human, material, etc.

· Develop awareness-raising activities targeting all levels of the organization. It is advisable to use the cascade strategy, which consists of raising awareness first at the highest hierarchical levels and then at the rest of the organization.

As organizations need to address various issues, problems or risks, ISO (2008) acknowledged that there is a demand for standards that describe the components of management systems, the adoption and implementation of which can have a significant impact on the operation and management of organizations' business processes. In addition, an increasing number of organizations are adopting not just one management system standard, but a set of standards that aim to meet the needs of internal and external stakeholders. In Peru, the Instituto Nacional de Calidad [Peruvian, National Quality Institute] (INACAL) has published fifteen Normas Técnicas Peruanas [Peruvian Technical Standards] (NTP) concerning management systems (Table 1). Depending on their business processes, organizations can voluntarily adopt one or more NTPs. Only two NTPs are mandatory for some Peruvian government entities. In 2011, with the enactment of Law No. 29783, Law on Occupational Safety and Health, it was established that it is mandatory for organizations, both public and private, to implement occupational health and safety management systems (Ley N° 29783, 2011), but the adoption of any NTP or other international standard was not specified.

Table 1. Peruvian Technical Standards Related to Management Systems.

|

Code |

Title |

|

NTP-ISO 9001 |

Quality management systems — Requirements |

|

NTP-ISO 13485 |

Medical devices — Quality management systems — Requirements for regulatory purposes |

|

NTP-ISO 14001 |

Environmental management systems — Requirements with guidance for use |

|

NTP-ISO 18091 |

Quality management systems — Guidelines for the application of ISO 9001 in local government |

|

NTP-ISO 19600 |

|

|

NTP-ISO 20121 |

Event sustainability management systems — Requirements with guidance for use |

|

NTP-ISO 21001 |

|

|

NTP-ISO 22000 |

Food safety management systems — Requirements for any organization in the food chain |

|

NTP-ISO 22301 |

Security and resilience — Business continuity management systems — Requirements |

|

NTP-ISO/IEC 27001* |

|

|

NTP-ISO 28001 |

|

|

NTP-ISO 37001** |

Anti-bribery management systems — Requirements with guidance for use |

|

NTP-ISO 45001 |

Occupational health and safety management systems — Requirements with guidance for use |

|

NTP-ISO 50001 |

Energy management systems — Requirements with guidance for use |

|

NTP-ISO 55001 |

Source: Normas Técnicas Peruanas (Instituto Nacional de Calidad [INACAL], n.d.)

(*) Mandatory for Sistema Nacional de Informática entities (Resolución Ministerial N° 129-2012-PCM)

(**) Mandatory for subjects in categories 1 and 2 under Law No. 30737 (Decreto Supremo N° 096-2018-EF)

The results of the Encuesta Nacional de Empresas 2015 [Peruvian National Business Survey] (Instituto Nacional de Estadística e Informática [INEI], 2016) revealed that none of the micro and small companies surveyed have any type of management system certification, and only 10. 3% of the medium and large companies surveyed have some type of certification, among which ISO 9001 (quality management) accounts for the highest acceptance with 58.8%, followed by ISO 14001 (environmental management) and OHSAS 18001 (occupational health and safety management) with 6.1% and 5.9%, respectively. The following are among the main reasons for implementing such standards:

· Enables companies to be more efficient-productive

· Local client requirements

The results of the 2020 ISO Survey (ISO, 2021) showed that 85.1% of the management system standards certificates issued in Peru correspond to ISO 9001, ISO 14001 and ISO 45001 (Table 2), but worldwide they account for 0.18%, 0.26% and 0.50% of the certificates issued, respectively.

Table 2. Number of ISO Management System Standards Certificates Issued.

|

Standard |

Number of Certificates |

Percentage |

|

ISO 9001 |

1631 |

43.2% |

|

ISO 14001 |

914 |

24.2% |

|

ISO 45001 |

667 |

17.7% |

|

ISO 37001 |

307 |

8.1% |

|

ISO 50001 |

93 |

2.5% |

|

ISO IEC 27001 |

85 |

2.3% |

|

ISO 39001 |

20 |

0.5% |

|

ISO IEC 20000-1 |

18 |

0.5% |

|

ISO 13485 |

15 |

0.4% |

|

ISO 22000 |

11 |

0.3% |

|

ISO 28000 |

8 |

0.2% |

|

ISO 22301 |

5 |

0.1% |

|

Total |

3774 |

100.0% |

Source: ISO (2021).

Based on the results of the 2015 National Business Survey and the 2020 ISO Survey, it is concluded that the level of implementation and certification of management systems in Peru is still low, considering that there are 2 734 619 formally constituted companies, a figure that includes micro, small, medium and large and public administration companies (INEI, 2021). On the assumption that each certificate issued corresponds to one company, only 0.14% of formally constituted companies are certified in some type of management system.

Studies in the field of agricultural chemical pesticides (agrochemicals) have focused mainly on the hazards associated with the handling of agrochemicals by workers in the agricultural sector. No research that addresses performance improvement as a result of the implementation of management systems in agrochemical-producing companies has been found, even though the production of agrochemicals is classified as a risk activity under Peruvian regulations (D. S. N° 003-98-SA., 1998), mainly due to the handling of large quantities of products and inputs categorized as “hazardous materials” (Naciones Unidas, 2019). Incidents may occur in this type of work activity that harm the physical and emotional integrity of workers (including workers of intermediary companies, outsourcing companies and contractors), in addition to impacting the community and the environment.

Standards ISO 14001 and ISO 45001 set the guidelines for environmental and occupational health and safety management systems, respectively, that organizations should adopt to comply with their environmental and occupational health and safety policies. They have been designed to meet the needs of any type of organization, be they service, production or public organizations by their nature, or micro, small, medium or large companies by their size, among other classifications; these standards set requirements that must be analyzed and adapted to the context and specific situation of each organization according to its own needs (ISO, 2015b; 2018).

At present, organizations face the challenge as to how to practically and simultaneously manage environmental care and the creation of safe and healthy environments; therefore, the purpose of the study was to “Design and implement an environmental, occupational health and safety management system (EHS-MS) in a Peruvian company of the agrochemical sector to improve its performance in the field of environment, occupational health and safety”. This objective, however, cannot be achieved without the proper implementation of the management system, for which a methodology for implementation is essential to articulate its elements, as well as to have a base structure for the management system. A methodology that adopts a module-based implementation structure is presented in this paper, as an alternative to the methodologies commonly used. Also, a base structure is established for the design of management systems that fully integrates the requirements of the ISO 14001 and ISO 45001 standards, and that complies with the applicable legal provisions.

METHODOLOGY

Research Type and Design

This is an explanatory research with a pre-experimental pretest-posttest design.

Research Company

The research was conducted at a company located in Metropolitan Lima specialized in the manufacture, repackaging and commercialization of agrochemical products. It should be noted that the company in question was already ISO 9001 certified at the time the research began.

Implementation Methodology

For the design and subsequent implementation of the EHS-MS, an implementation methodology was established as follows, from the perspective of a total integration strategy (Ferguson et al., 2002; Block & Marash, 2000):

· Stage I: Diagnosis

· Stage II: Design and implementation

· Stage III: Audit and review by Management

· Stage IV: Certification (optional)

Stage I had the purpose of establishing the state of the management system in order to identify its strengths and weaknesses in terms of environmental management, occupational health and safety, thus making it possible to determine the gap in relation to the standards to be implemented (Mata et al., 2019).

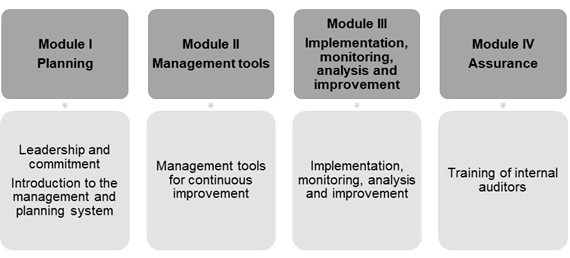

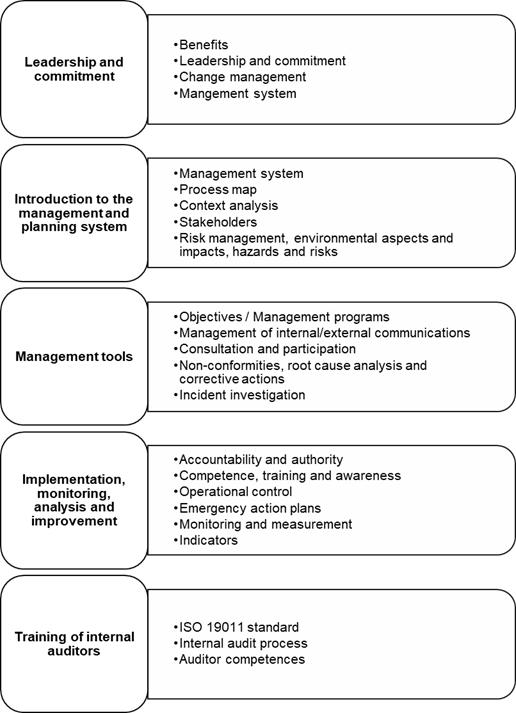

Stage II was conducted using a four-module implementation scheme, combined with training activities. Figure 1 shows the four implementation modules and the corresponding training activities, and Figure 2 shows the agenda for each training activity.

Figure 1. Module Implementation Scheme and Training Activities.

Source: Prepared by the author.

Figure 2. Agenda of Training Activities.

Source: Prepared by the author.

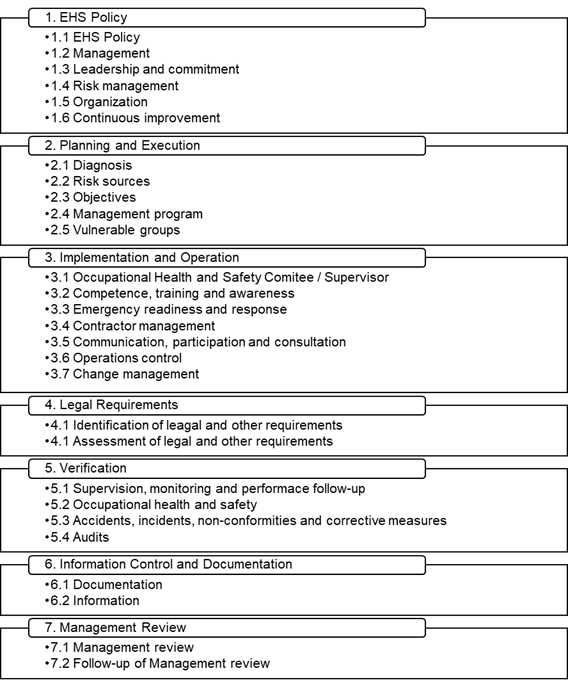

Figure 3 shows the structure of the EHS-MS (criteria and subcriteria), designed based on the structure of the Basic Guide proposed by R. M. N° 050-2013-TR (2013), to which the requirements of ISO 14001 and ISO 45001 standards were incorporated, as well as national and international regulations.

Figure 3. EHS-MS Criteria and Subcriteria.

Source: Prepared by the author.

An internal audit was carried out during Stage III to verify whether the management system was consistent with the requirements of ISO 14001 and ISO 45001 standards and conformed to the company’s own requirements, as well as whether the management system was fully implemented and effectively maintained (ISO, 2015b; 2018). Therefore, it is advisable to pay special attention to internal audits as this will allow for proper implementation of the management system (Delgado et al., 2019). Similarly, reviewing the management system ensures its continuous suitability, adequacy, effectiveness and alignment with the strategic course of the organization.

Although Stage IV is optional, if organizations are to be successful in the market, it is necessary that they not only implement and maintain their management system, but also certify it (Ticona, 2019).

A timeframe of eight months was considered for the design and implementation of the EHS-MS, which was determined in conjunction with the Management of the company under study.

Data Collection and Interpretation

Checklists developed for each standard, ISO 14001 and ISO 45001, were used for Stage I, where data on the status of the management system of the company under study was recorded. During Stage II, electronic forms were designed to collect data on solid waste, energy, occupational accidents and occupational diseases in order to calculate the performance indicators in Table 3. During Stages III and IV, data was collected from the audit reports and the management review report.

Table 3. Performance Indicators.

|

Indicator |

Description |

Calculation Formula |

|

Area: Environment |

||

|

Solid waste generation |

Quantification of the ratio of the amount of hazardous and non-hazardous solid waste generated during operations divided by production volume |

Kilograms of solid waste generated / units produced |

|

Active power use off-peak hours |

Quantification of power consumption during operations that do not take place from 18:00 to 23:00 hours divided by production volume |

kW per hour / units produced |

|

Active power use during peak hours |

Quantification of electricity consumption during operations from 18:00 p.m. to 23:00 hours divided by production volume. |

kW per hour / units produced |

|

Area: Safety |

||

|

Accident frequency rate (FR) |

Quantification of the ratio of lost-time accidents divided by the total number of man-hours worked multiplied by the factor of one million man-hours |

Number of lost-time accidents * 1000000 / man-hours |

|

Accident severity rate (SR) |

Quantification of the ratio of lost days divided by total man-hours worked multiplied by a factor of one million man-hours |

Number of lost workdays * 1000000 / man-hours |

|

Accident rate |

Quantification of the ratio of the frequency rate multiplied by the severity rate divided by the factor of one thousand |

FR * SR / 1000 |

|

Area: Occupational Health |

||

|

Occupational medical examination results |

Quantification of medical fitness results: fit, fit with restrictions and unfit. |

Medical fitness |

Source: Prepared by the author.

For the analysis and interpretation of the data, trend tables and charts were used to evaluate the evolution of the indicators in Table 3. IBM SPSS Statistics 25 was used to evaluate the normality of the data using the Shapiro-Wilk test (sample of less than 30 data), as well as to apply the nonparametric Wilcoxon test.

RESULTS

Environmental Performance

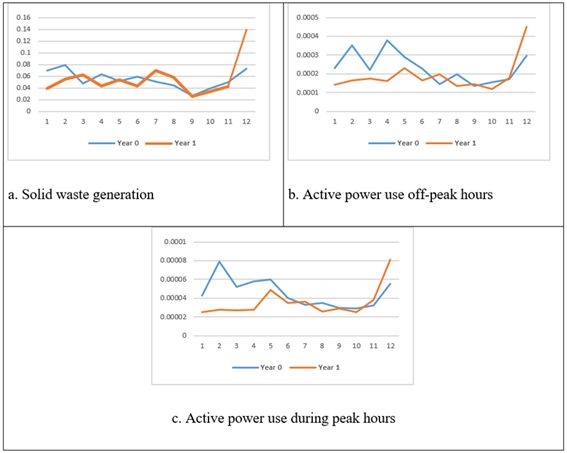

Three environmental performance indicators related to hazardous and non-hazardous solid waste, two related to the generation of non-municipal hazardous and non-hazardous solid waste, and one indicator related to power consumption were analyzed. Table 4 shows the annual results and Figure 4 shows the monthly results.

Table 4. Environmental Performance Results (annual values).

|

Performance Indicators |

Unit |

Year 0 |

Year 1 |

|

Solid waste generation |

kg SW/ PU |

0.052 |

0.050 |

|

Active power use off-peak hours |

kWh / PU |

0.000214 |

0.000172 |

|

Active power use during peak hours |

kWh / PU |

0.000042 |

0.000033 |

Source: Prepared by the author.

SW: solid waste / PU: production unit / kWh: kilowatt / hour

Figure 4. Monthly Environmental Performance Results.

Source: Prepared by the author.

Safety Performance

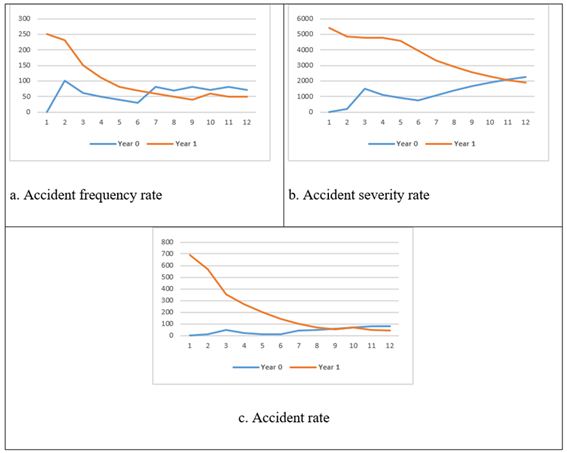

The rates set out in the register of occupational safety and health statistics, approved by R. M. N° 050-2013-TR N° 050-2013-TR (2013), were used. Table 5 presents the annual results and Figure 5 shows the monthly results.

Table 5. Safety Performance Results (annual values).

|

Performance Indicator |

Unit |

Year 0 |

Year 1 |

|

Accident frequency rate |

--- |

7.8 |

5.1 |

|

Accident severity rate |

--- |

227.3 |

191.8 |

|

Accident rate |

--- |

8.9 |

4.9 |

Source: Prepared by the author.

Figure 5. Monthly Safety Performance Results.

Source: Prepared by the author.

Occupational Health Performance

The annual results of the medical fitness determined in the periodic occupational medical examinations are shown in Table 6. It should be mentioned that the company under study proactively established an annual frequency of periodic occupational medical examinations, despite the fact that the current regulations state that the frequency should be every two (2) years.

Table 6. Occupational Health Performance Results (annual values).

|

|

Medical Fitness of Workers |

||||

|

Fit |

Fit with Restrictions |

Unfit |

Total |

||

|

Year 0 |

Frequency |

33 |

29 |

1 |

63 |

|

% |

52.4 |

46.0 |

1.6 |

100.0 |

|

|

Year 1 |

Frequency |

25 |

26 |

0 |

51 |

|

% |

49.1 |

50.9 |

0.0 |

100.0 |

|

Source: Prepared by the author.

Inferential Analysis

Using the Shapiro-Wilk normality test (Table 7), it was determined that the data for year 0 are normal for a significance level of 5%, which differs from the data for year 1. It was concluded that the data are not normal, therefore, the nonparametric Wilcoxon test (Table 8) was used and the following hypotheses were formulated:

H0: The median of the differences between the year 0 and year 1 indicators is equal to zero.

H1: The median of the differences between the indicators for year 0 and year 1 is different from zero.

Table 7. Results of the Shapiro-Wilk Normality Test.

|

Indicator |

Year 0 |

Year 1 |

||||

|

Statistic |

df |

Sig. |

Statistic |

df |

Sig. |

|

|

Solid waste generation |

0.981 |

12 |

0.988 |

0.746 |

12 |

0.002 |

|

Active power use off-peak hours |

0.925 |

12 |

0.334 |

0.639 |

12 |

0.000 |

|

Active power use during peak hours |

0.903 |

12 |

0.173 |

0.682 |

12 |

0.001 |

|

Accident frequency rate |

0.911 |

12 |

0.220 |

0.755 |

12 |

0.003 |

|

Accident severity rate |

0.970 |

12 |

0.907 |

0.904 |

12 |

0.181 |

|

Accident rate |

0.940 |

12 |

0.498 |

0.790 |

12 |

0.007 |

Source: Prepared by the author.

Table 8. Wilcoxon Test Results.

|

Indicator |

P-value |

Decision |

|

Solid waste generation |

0.583 |

Accept H0* |

|

Active power use off-peak hours |

0.099 |

Reject H0** |

|

Active power use during peak hours |

0.084 |

Reject H0** |

|

Accident frequency rate |

0.170 |

Accept H0* |

|

Accident severity rate |

0.005 |

Reject H0* |

|

Accident rate |

0.028 |

Reject H0* |

Source: Prepared by the author.

(*) At a significance level of 0.05

(**) At a significance level of 0.10

DISCUSSION

Indicator “solid waste generation” shows a reduction of 3.8% (Table 4), resulting from the implementation of strategies to minimize, segregate at the source, and reuse waste. An estimated S/ 5 858.44 was saved by disposing of solid waste in safe sanitary landfills, and an income of S/ 44 335.46 was obtained from the commercialization of reusable waste. These profits financed actions to benefit the workers, such as the purchase of a television set that was installed in the canteen and training activities with hired external instructors. No significant statistical differences were found between the years examined (Table 8), indicating that waste generation may be due to the variety of materials and inputs used for product formulation and repackaging, and to the fact that in the last month of each year expired products are destroyed for accounting purposes and treated as solid waste (Figure 4.a). The presence of expired products is due to the recovery of products from clients with debts or payment problems.

Indicators “active power use off-peak hours” and “active power use during peak hours” show a reduction of 19.6% and 21.4%, respectively (Table 4), resulting from the segmentation of the electrical systems, in addition to the installation of timers for the internal and external lighting system. A significant difference was found between the evaluated years (Table 8), although there were peaks during December in both years (Figure 4.b and 4.c), possibly explained by the billing cycles of the electric company that do not correspond to the monthly production schedule. The favorable results of the three environmental performance indicators are consistent with those found in the studies of Franco and Arias (2018) and Tlapa et al. (2009).

The “accident frequency rate”, “accident severity rate” and “accident rate” showed a reduction of 34.6%, 15.6% and 44.9%, respectively (Table 5). This reduction was achieved thanks to hazard identification, risk assessment and the implementation of operational controls. The improvement in the safety rates made it possible to restore the availability of the workforce by reducing the number of lost-time work accidents, which translates into fewer work days lost.

Statistically, it was found that the “accident severity rate” and the “accident rate” differed significantly between the years evaluated; in other words, there is evidence of the influence of the EHS management system on these indicators. These favorable results differ from those reported by Riaño-Casallas et al. (2016), Vinodkumar and Bhasi (2011) and Chang and Liang (2009), since no clear trend of decreasing severity rates in the studied companies was found in their research.

As the evaluation period was short, no significant statistical difference was found between the years evaluated for the “accident frequency rate”, but it is expected that this indicator will tend to decrease significantly as the management system reaches a higher degree of maturity, in agreement with that stated by Obando-Montenegro et al. (2019).

As shown in Table 6, it was possible to improve the results of medical aptitude “fit” and “fit with restrictions”, and the results “unfit” were completely eliminated. Two monitoring programs were designed and implemented for workers with “fit with restrictions” medical aptitude: respiratory protection due to the presence of chemical agents (dusts and fumes from chemical products and inputs) and hearing protection due to exposure to continuous noise above 85 dB.

CONCLUSIONS

The adoption of ISO 14001 and ISO 45001 standards, within the framework of national and international regulations, for the design of the EHS-MS for the company under study integrated the principles of continuous improvement, legal compliance, environmental protection, and prevention of injuries and deterioration of health due to occupational accidents and diseases. The design of the EHS-MS was based on a structure of seven (7) criteria with 28 sub-criteria.

The planned 8-month timeframe for the implementation of the EHS-MS was met, using the module implementation scheme. Organizations should have previously implemented process management, as this will contribute to the integration of the ISO 14001 and ISO 45001 standards in the design of the EHS-MS.

The EHS-MS contributed to the improvement of environmental performance through the management of solid waste and electrical energy. Safety performance was also improved, as reflected in the reduction of frequency, severity, and accident rates. Finally, occupational health performance improved, as evidenced by the encouraging results of workers’ medical aptitude.

As part of risk management, it is important for the company under study to identify potential threats that could threaten the continuity of the results obtained.

REFERENCES

[1] Block, M., & Marash, I. (2000). Integración de ISO 14001 en un Sistema de Gestión de la Calidad. Madrid, Spain: AENOR.

[2] Cabalé, E., & Rodríguez, G. (2020). Sistemas de gestión. Importancia de su integración y vínculo con el desarrollo. Revista Estudios del Desarrollo Social: Cuba y América Latina, 8(1), http://scielo.sld.cu/scielo.php?script=sci_arttext&pid=S2308-01322020000100018

[3] Chang, J., & Liang, C. L. (2009). Performance evaluation of process safety management systems of paint manufacturing facilities. Journal of Loss Prevention in the Process Industries, 22(4) 398-402. https://doi.org/10.1016/j.jlp.2009.02.004

[4] Clark, M., Hernández, A., Menéndez, M., Peguero, H., & Tennison, R. (2019). Diagnóstico de aspectos e impactos medioambientales en la Facultad de Estomatología de la Habana. Revista Información Científica, 98(1), 29-43.

[5] David, F. R. (2008). Conceptos de Administración Estratégica. Naucalpan de Juárez, Mexico: Pearson Educación.

[6] Decreto Supremo N.° 003-98-SA. Aprueban Normas Técnicas del Seguro Complementario de Trabajo de Riesgo. Diario Oficial El Peruano (1998, 14 de abril).

[7] Delgado, M., Cabrera, M., & Pérez, G. (2019). Análisis para la Implementación del Sistema de Gestión de Calidad y del Sistema de Gestión Ambiental para el Laboratorio de Análisis Instrumental de la Escuela Politécnica Nacional. Revista Politécnica, 42(2), 57-62. https://doi.org/10.33333/rp.vol42n2.959

[8] Estrada, A. M. (2018). Guía para la implementación de un sistema de gestión integral en la empresa Óptima de Urabá S.A. E.S.P. Signos, 10(1), 77-101. https://doi.org/10.15332/s2145-1389.2018.0001.04

[9] Ferguson, M., García, M., & Bornay, M. (2002). Modelos de implantación de los sistemas integrados de gestión de la calidad, el medio ambiente y la seguridad. Investigaciones europeas de dirección y economía de la empresa, 8(1), 97-118. https://dialnet.unirioja.es/servlet/articulo?codigo=251464

[10] Franco, C., & Arias, J. (2018). Sistemas de gestión ambiental y procesos de producción más limpia en empresas del sector productivo de Pereira y Dosquebradas. Entre Ciencia e Ingeniería, 140-146. https://doi.org/10.31908/19098367.3714

[11] Instituto Nacional de Calidad. (n.d.). Normas Técnicas Peruanas. https://servicios.inacal.gob.pe/datos_abiertos/NormaTecnica

[12] Instituto Nacional de Defensa de la Competencia y de la Protección de la Propiedad Intelectual. (2006). Guía de aplicación de Sistemas Integrados de Gestión: ISO 9001, ISO 14001 y OHSAS 18001 (NTP 833.906:2006).

[13] Instituto Nacional de Estadística e Informática. (2016). Perú - Encuesta Nacional de Empresas 2015. http://webinei.inei.gob.pe/anda_inei/index.php/catalog/653

[14] Instituto Nacional de Estadística e Informática. (2021). Perú: Estructura Empresarial 2019. https://www.inei.gob.pe/media/MenuRecursivo/publicaciones_digitales/Est/Lib1817/libro.pdf

[15] Jimenez, R., & Nuñez, S. (2014). Evaluación del desempeño ambiental basado en la norma técnica ISO 14001:2004 con el fin de determinar estrategias para su implementación en la Universidad de Cundinamarca. Signos, 6(2), 75-86. https://revistas.usantotomas.edu.co/index.php/signos/article/view/2738

[16] La Madrid, C. (2008). Propuesta de un plan de seguridad y salud para obras de construcción. (Tesis de grado). Pontificia Universidad Católica del Perú, Lima. http://hdl.handle.net/20.500.12404/181

[17] Ley N.° 29783. (2011, sábado 20 de agosto). Ley de seguridad y salud en el trabajo. Diario Oficial El Peruano.

[18] Mata, M., Cabrera, H., & Rodríguez, B. (2019). Experiencia en la medición del grado de madurez de un SGC en comercializadora de cementos. Revista Universidad y Sociedad, 11(2), 318-330.

[19] Naciones Unidas. (2019). Recomendaciones relativas al transporte de mercancías peligrosas. Reglamentación modelo.

[20] Obando-Montenegro, J., Sotolongo-Sanchez, M., & Villa-González del Pino, E. (2019). Evaluación del desempeño de seguridad y salud en una empresa de impresión. Ingeniería Industrial, XL(2)136-147.

[21] Organización Internacional para la Normalización. (2008). Annual Report 2008. https://www.iso.org/annual-reports.html

[22] Organización Internacional para la Normalización. (2015a). Sistemas de gestión de la calidad — Fundamentos y vocabulario (ISO 9000:2015).

[23] Organización Internacional para la Normalización. (2015b). Sistemas de gestión ambiental – Requisitos con orientación para su uso (ISO 14001:2015).

[24] Organización Internacional para la Normalización. (2018). Sistemas de gestión de seguridad y salud en el trabajo – Requisitos con orientación para su uso (ISO 45001:2018).

[25] Organización Internacional para la Normalización. (2021). ISO Survey 2020. https://isotc.iso.org/livelink/livelink?func=ll&objId=22271895&objAction=browse&viewType=1

[26] Posada, P. R. (2011). Diseño y desarrollo de un sistema de gestión de seguridad y salud ocupacional OHSAS 18001:2007 para una empresa importadora, distribuidora y comercializadora de productos agroquímicos. (Undergraduate thesis). Escuela Superior Politécnica del Litoral, Guayaquil. http://www.dspace.espol.edu.ec/handle/123456789/14214

[27] Resolución Ministerial N° 050-2013-TR. Aprueban Formatos Referenciales que contemplan la información mínima que deben contener los registros obligatorios del Sistema de Gestión de Seguridad y Salud en el Trabajo. Diario Oficial El Peruano (2013, 14 de marzo).

[28] Riaño-Casallas, M. I., Hoyos, E., & Valero, I. (2016). Evolución de un sistema de gestión de seguridad y salud en el trabajo e impacto en la accidentalidad laboral: Estudio de caso en empresas del sector petroquímico en Colombia. Ciencia & trabajo, 18(55), 68-72. http://dx.doi.org/10.4067/S0718-24492016000100011

[29] Tapia, L. T. (2013). Propuesta de guía metodológica para la implementación de un sistema integrado de gestión de calidad, ambiente y seguridad. Caso: Industria Multinacional Cosmética de Venta Directa, productos Avon Ecuador S.A. (Tesis de maestría). Universidad Politécnica Salesiana Ecuador, Guayaquil. http://dspace.ups.edu.ec/handle/123456789/5366

[30] Ticona, A. (2019). Beneficio de la implementación de las normas ISO 9001 e ISO 14001. (Trabajo de Suficiencia Profesional). Universidad Nacional del Antiplano, Puno. http://repositorio.unap.edu.pe/bitstream/handle/UNAP/12493/Ticona_Fernandez_Abdul.pdf?sequence=1&isAllowed=y

[31] Tlapa, D., Limón, J., & Báez, Y. (2009). Gestión de la Calidad y del Medio Ambiente en Instituciones de Educación Superior mediante Integración de ISO 9001 e ISO 14001. Formación universitaria, 2(2) 35-46. DOI: http://dx.doi.org/10.4067/S0718-50062009000200006

[32] Vinodkumar, M., & Bhasi, M. (2011). A study on the impact of management system certification on safety management. Safety Science, 49(3), 498-507. https://doi.org/10.1016/j.ssci.2010.11.009

[33] Yamuca Santos, E. (2010). Diseño de un sistema de gestión ambiental basado en la norma ISO 14001:2004 para una fábrica de cemento. (Undergraduate thesis). Pontificia Universidad Católica del Perú, Lima. http://hdl.handle.net/20.500.12404/531