Revista Industrial Data 27(2): 7-31 (2024)

DOI: https://doi.org/10.15381/idata.v27i2.23859

ISSN: 1560-9146 (Impreso) / ISSN: 1810-9993 (Electrónico)

Optimizing Pb-Ag Recovery Rate in the

Flotation Process of Polymetallic Ores from the Northern Andean Region of Peru through

Mineralogical Characterization

Design and

Technology

Submitted:

26/10/2022 Accepted: 13/09/2023 Published: 18/12/2024

https://doi.org/10.15381/idata.v27i2.23859.g204481

José David Valverde Díaz

Vidal Sixto Aramburú Rojas

Jorge Alberto Ortiz Barreto

Sharon Elisa Aguilar Zevallos

ABSTRACT

A mineralogical characterization study to optimize

lead-silver (Pb-Ag) recovery rate by flotation was conducted at three adits named

Esmeralda, Orión, and Hércules. The variables investigated included the dosage

of the reagent blend (AP-3418/AR-404), AR-242, and pH. At the Esmeralda adit, a

recovery of 81.99% lead at a concentrate grade of 58.66% and 83.79% silver at a

head grade of 310.64 oz/t was achieved using a dosage of 18 g/t reagent blend

(AP-3418/AR-404), 5 g/t AR-242, and an optimum pH value of 11.5. At the Orión adit,

a recovery of 81.71% lead at a concentrate grade of 61.6%, and 81.24% silver at

a head grade of 85.39 oz/t were achieved using a dosage of 30 g/t reagent blend

(AP-3418/AR-404), 5 g/t AR-242, and an optimum pH value of 10.5. Finally, at

the Hércules adit, a recovery of 82.4% lead at a concentrate grade of 54.12%,

and 80.88% silver at a head grade of 62.63 oz/t grade were achieved using a

dosage of 30 g/t reagent blend (AP-3418/AR-404), 15 g/t AR-242, and a pH value

of 11.5.

Keywords:

characterization, Minitab, adit, flotation.

INTRODUCTION

Until the end of 2019, Peru ranked as the second-largest silver producer

and the third-largest lead producer in the world, according to a report by the

United States Geological Survey (2019). However, from 2020 onwards, there has

been a decline in the production of these metals. As a result, Peru has dropped

to the third and fourth positions for silver and lead production worldwide,

respectively, surpassed by China and the United States, according to figures

reported by the Peruvian Statistical Mining Bulletin (Ministerio de Energía y

Minas, 2022).

The lead content of natural galena is generally low, requiring

concentration to obtain a commercial product (Yekeler & Yekeler, 2006).

Flotation has been the conventional method for recovering polymetallic ores,

with low production costs and low environmental impact. As a result, it remains

irreplaceable in the processing of sulfide ore resources (Xie et al., 2021).

Notably, about 95% of global lead production comes from its sulfide species

(Zou et al., 2022). The success of the flotation process can be attributed to

the ability of the chemical reagents to form stable complexes with metal ions

in aqueous solutions or on ore surfaces. This enhances the physical and

chemical properties of the surface, allowing for the selective separation of

sulfide species from the gangue (Chen, 2021). Dithiophosphoric acid compounds

have been developed as flotation collectors for the sulfide species of lead,

among them, dithiophosphate (DTP) and dithiophosphinate (DTPI) are the most

widely used due to their high selectivity in galena concentration (Tercero et

al., 2019). Concentrating galena with xanthate-type collectors is also

possible, which do not hydrolyze, oxidize, or decompose into other species,

unlike dithiophosphates (Elizondo et al., 2021; Shen et al., 2016).

Silver is often found as a trace or minor component in galena; as a

result, less attention is often given to silver recovery compared to the main

component (Ayllón, 2013;

Aranda, 2014; Nassar et al., 2015; Song et al., 2021). However, the

significance of silver has grown due to its role in the development of green

technologies, such as solar panels and hybrid vehicles. This has made

optimizing silver production during the flotation process critical for the

mining and metallurgical sectors (Tiu et al., 2021). Furthermore, silver is

recognized as one of the essential materials needed to achieve the Sustainable

Development Goals (SDGs) set for 2030 (Dou et al., 2023).

Astucuri (1994)

discusses the intricate physical and chemical characteristics of certain

species, emphasizing the need for a thorough geological characterization of the

deposits that contain them. This process involves identifying and quantifying

mineral species, their volumetric distribution, degrees of liberation, and the

associations in the ore; it also includes analyzing rock structures associated

with the deposit (Yovanovic, 2004; Melgarejo et al., 2010; Bertolino et al.,

2014; Ramos & Orihuela, 2017; Taya, 2018). Such detailed information is

crucial for assessing the impact of the species involved in mineral processing;

it aids in effectively segmenting the deposit and optimizing the recovery of

valuable species (López & Ipanaqué, 2008; Bustamante et al., 2008; Ojeda et

al., 2010; Espinoza et al., 2021).

Among the conventional techniques used for the characterization of

mineral species are X-ray powder diffraction (XRD), quantitative X-ray

diffraction, scanning electron microscopy and energy dispersive X-ray

spectroscopy (SEM-EDS), cathodoluminescence, and electron microprobe (EMP).

These are widely used due to their relatively low cost. In contrast,

non-conventional techniques such as particle-induced X-ray emission

(Micro-PIXE), secondary ion mass spectrometry (SIMS), and laser ablation

inductively coupled plasma mass spectrometry (LA-ICP-MS) are less accessible

and significantly more expensive (Melgarejo et al., 2010; Alves, 2014).

Song et al. (2021) investigated

the flotation of silver-bearing galena using collectors such as dibutyl

ammonium dithiophosphate (ADD), ethyl xanthate (EX), and diethyldithiocarbamate

(DDC). They found that silver-bearing galena is more effectively floated at a

pH level of 9.5. The results indicated that the ADD collector yielded better

recovery rates than both the EX and DDC collectors. The authors conducted micro-flotation

experiments on 2 g samples ground to 100% −200 mesh. They also performed

conventional flotation tests in a 1500 ml flotation cell using 500 g of raw ore

ground to 80% −74 microns, an agitation rate of 1500 rpm, and an airflow rate

of 20 L/min. To further investigate the behavior of silver-bearing galena, the

authors conducted simulations based on the density functional theory (DFT)

method. The best flotation tests using the ADD collector achieved a recovery

rate of 85% for galena and over 90% for silver-bearing galena.

This research paper is relevant because it uses experimental designs and

analysis of variance to determine the optimal dosage of reagents for maximizing

the recovery rate and quality of Pb-Ag concentrate. The calculated reagent

dosages aim to predict recovery percentages and quality in polymetallic

deposits located in the northern Andean region of Peru. Additionally, this

research contributes to the improvement and optimization of outcomes in Pb and

Ag mining, while also enhancing the academic understanding related to their

extraction.

Optimizing lead-silver recovery rate in the

flotation process of polymetallic ores from the Andean region of Peru through mineralogical

characterization and experimental designs.

Specific

Objectives

· Identify the sample components, degrees of

liberation, and the presence of free and interlocked grains from the Esmeralda,

Orión, and Hércules adits in the Andean region of Peru.

·

Determine the influence

of the reagent blend (AP-3418/AR-404) dosage, AR-242, and the pH of the pulp,

along with their contributions to the flotation process using Plackett-Burman

experimental designs and Minitab statistical software.

·

Optimize the lead and

silver recovery rate in the flotation process of polymetallic ores from three adits

located in the Andean region of Peru.

General Hypothesis

Mineralogical characterization and experimental designs optimize the lead-silver

recovery rate by the flotation process of polymetallic ores in the Andean region

of Peru.

Specific

Hypotheses

·

Mineralogical

characterization allows for the identification of the mineral species present

in a sample, as well as the degrees of liberation and bonds found in various

mineralogical formations.

·

Analyzing the

interaction of reagent blend (AP-3418/AR-404) dosages, AR-242, and the pH of

the pulp using Plackett-Burman experimental designs in Minitab statistical

software helps determine the extent of their contribution to the flotation

process in various adits.

·

Optimizing the lead and

silver recovery rate by flotation leads to improved metallurgical performance.

Theoretical Justification

The optimization of reagent dosage and pulp alkalinity in the flotation

process enhances the metallurgical performance of lead-silver

concentrates, thereby improving concentrate quality and resulting in a positive

economic impact.

Practical Justification

The identification of species is essential for characterizing each

mineralogical formation involved in the concentration process. This

understanding is important to optimize the recovery rate of the concentrate

through flotation of polymetallic ores, considering reagent dosage and pulp

alkalinity variables, in the Andean regions of Peru. Furthermore, the findings

of this study can serve as a model for other mines with similar mineralogy,

improving lead and silver recovery using experimental designs in flotation.

Economic Justification

Effective management of raw materials is essential for optimizing the

production of metallurgical mining resources, which can significantly enhance

the revenue of a concentrator plant.

Social Justification

From a social perspective, optimizing resource use in the processing of

polymetallic ores through the flotation process benefits both directly and

indirectly involved communities. Thus, this approach helps guarantee local

employment and fosters community development for future generations.

METHODOLOGY

This research employs a quantitative, deductive, and experimental design

methodology. It applies knowledge of mineralogical characterization and

analyzes the variables influencing the flotation process, which facilitates the

optimization of the lead-silver concentrate recovery rate. The research

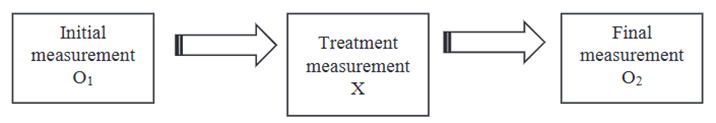

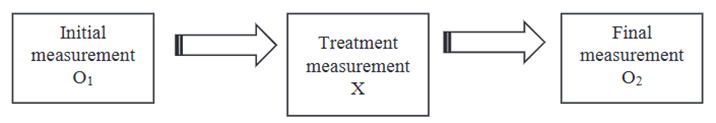

follows a specific design framework as shown in Figure 1.

Figure 1. Methodological

scheme of the research.

Note. The figure

illustrates the measurements included in the research design for this study.

Source: Prepared by the authors.

O1: Mineralogical characterization of the Esmeralda, Orión,

and Hércules adits.

X: Development of the Plackett-Burman

experimental design and analysis of the variables influencing the metallurgical

flotation process.

O2: Optimization of lead and silver recovery in the high

Andean region of Peru.

Research Method Procedure

·

Sampling and Sample Preparation

A representative sample of polymetallic ore was

collected from the Esmeralda, Orión, and Hércules adits. Using a jaw crusher, this

sample was then ground to 100% passing through a 10 mesh. To ensure thorough

research testing, the entire sampled batch was quartered, and a portion was

stored as a control sample.

·

Chemical Assays and

Mineralogical Characterization

A representative ore sample was ground in a ball mill

to determine the head grades of lead (Pb) and silver (Ag). Additionally,

samples of different gradation (+100 mesh, <−100, +200] mesh, and <−200,

+400] mesh) from the study adits were sent to the mineralogical

characterization laboratory to identify the mineral species present, assess

volumetric distribution, determine degrees of liberation, and evaluate associations

or bonds present. The mineralogical analysis was performed using a polarized

light microscope.

·

Experimental Designs Using Minitab

19

Plackett-Burman experimental designs were generated

using Minitab 19 statistical software to assess the independent variables that

significantly influence the recovery and quality of lead-silver

concentrate, as well as to optimize the flotation process. A test plan was

established based on the Plackett-Burman template provided by the software to

assess the impact of the reagent blend (AP-3418/AR-404, AR-242) and the pH of

the pulp on the recovery and quality of the lead-silver concentrate. Other

process variables were kept constant during the laboratory metallurgical

flotation tests.

RESULTS

Chemical Assays

The chemical assays for lead (Pb) in the study adits were conducted using

the volumetric analysis, while silver (Ag) head grades were determined through

cupellation. Laboratory reports indicated that the Esmeralda adit exhibited the

highest silver head grade (6.65 oz/t), whereas the Hércules adit showed the

lowest silver head grade (1.12 oz/t). Additionally, the reports on lead

concentration revealed that the Orión adit had the highest lead head grade (1.46%).

The results of the chemical assays conducted in the study adits are summarized

in Table 1 below.

Table 1. Chemical Assays Performed on Samples from the Adits.

|

Adit

|

Ag head grade

(oz/t)

|

Pb head grade

(%)

|

|

Esmeralda

|

6.65

|

1.22

|

|

Orión

|

1.59

|

1.46

|

|

Hércules

|

1.12

|

0.89

|

Note. The table displays the Ag-Pb head grades for the

Esmeralda, Orión, and Hércules adits.

Source: Prepared by the authors.

Volumetric Distribution of the Esmeralda, Orión, and Hércules Adits

The analysis of a representative sample from the Esmeralda adit, observed

under a polarizing light microscope, revealed that the primary lead-bearing

minerals are galena and lead sulfosalts. These minerals were predominantly

found in the particle size range of (−74 µ + 37 µ). Contaminating minerals such

as arsenopyrite were identified, with a significant distribution of 3.62%. Sphalerite

I and II were also identified, showing distribution values of 2.4% and 0.48%,

respectively. The presence of fahlores was noted with a distribution of 0.19%,

and stibnite was found with a distribution of 0.33%, all achieved at the

particle size distribution range of (−74 µ + 37 µ).

The mineralogical characterization of a representative sample from the

Orión adit determined that galena is the main lead-bearing species. The highest

distribution of this species occurs at a particle size smaller than 74 µ, with

a reported value of 1.02%. Contaminant ores, such as arsenopyrite, were also identified,

showing the highest distribution of 3.81% at a particle size smaller than 200

mesh. Sphalerite I and II were also identified, showing distribution values of

2.61% and 0.35%, respectively, at a particle size smaller than 200 mesh. The

presence of fahlores was noted with a maximum value of 0.08% retained on 200

mesh, and stibnite was found with a distribution of 0.41% achieved at a

particle size distribution range of 100% −200 mesh.

The analysis conducted for the Hércules adit revealed that galena is the

primary lead-bearing mineral, with a maximum distribution value of 2.21% at a particle

size smaller than 200 mesh. Arsenopyrite was also detected with a maximum

distribution of 4.95% at particles larger than 74 µ, while type I sphalerite

exhibited a maximum distribution of 13.25% at particles smaller than 74 µ.

Notably, the volumetric distribution of type I sphalerite was the highest

compared to other adits. It is important to mention that fahlores, type II sphalerite,

and stibnite were not reported.

The volumetric distribution values of all minerals identified under the

reflected light optical microscope are shown in Table 2, categorized by gradation:

+100 mesh, <−100, +200] mesh, and <−200, +400] mesh. The data shows that

these minerals are found in greater volumes at finer particle sizes, suggesting

that the species are liberated in this range of particle size distribution.

Degree of Liberation of Minerals from Esmeralda, Orión, and Hércules Adits

The mineral liberation analysis conducted at Esmeralda adit to determine

the degree of liberation of galena and sulfosalts reported values of 86.08% and

78.82%, respectively, at a particle size of 100% −200 mesh. Regarding

contaminants, arsenopyrite exhibited a degree of liberation of 95.06%; fahlores

showed a degree of liberation of 76.88%; sphalerite revealed a degree of

liberation of 100%; and stibnite showed a degree of liberation of 91.66%. These

values were determined at a particle size smaller than 200 mesh. Additionally,

the highest degree of liberation for type I sphalerite was found at a particle

size of 100% −100 mesh.

The mineral liberation analysis conducted at Orión adit revealed that

galena exhibited a degree of liberation value of 91.72% at a particle size

smaller than 200 mesh. At this same particle size distribution, the maximum

degrees of liberation were found for type I sphalerite, arsenopyrite, and

stibnite, with values of 95.2%, 95.11%, and 97.63%, respectively. Notably, type

II sphalerite exhibited the highest degree of liberation of 93.55% for material

retained on 100 mesh, while fahlores showed a value of 88.9% for material

retained on 200 mesh.

The mineral liberation analysis conducted at Hércules adit revealed that

galena was found to be 97.62% liberated at a particle size of 100% −200 mesh.

In contrast, the minerals considered detrimental to the process such as

sphalerite I, sphalerite II, and arsenopyrite reported liberation values of

96.14%, 44.89%, and 97.38%, respectively, at a particle size range of <−100,

+200] mesh. The total degrees of liberation for the identified species at

various gradations are summarized in Table 3.

Types of bonding between Pb and Ag

A representative sample from the Esmeralda adit was analyzed to determine

the bonds present. Considering a particle size of 100% +100 mesh, galena was

found to form bonds with pyrite, gangue, fahlores, and type I sphalerite, all

of which were reported to be moderately easy to liberate. At a particle size of

100% −100mesh, galena formed bonds

with arsenopyrite, pyrite, gangue, and fahlores. The bonds formed with gangue,

pyrite, and arsenopyrite were reported to be very difficult to liberate. At a

particle size of 100% −200 mesh, galena formed bonds with fahlores, lead

sulfosalts, type I sphalerite, arsenopyrite, stibnite, and chalcopyrite. Among

these, the bonds with fahlores were described as moderately difficult to

liberate, while those with lead sulfosalts were classified as very difficult.

Similarly, a representative sample from the Orión adit was also analyzed

to determine the bonds present. Considering a particle size of 100% +100 mesh,

galena formed bonds with arsenopyrite, which was found to be very difficult to

liberate. At a particle size of 100% −100 mesh, the bonds formed between galena

and chalcopyrite were deemed very difficult to liberate. Finally, at a particle

size of 100% −200 mesh, the bond formed between galena and arsenopyrite was considered

impossible to liberate.

In contrast, the bonds formed between galena and other minerals found in

a representative sample from the Hércules adit were reported to be easy to

liberate.

A comprehensive description of the observed bonds and their liberation

potential for the various samples is detailed in Table 4. Additionally, Figures

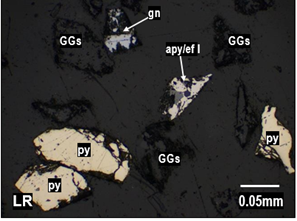

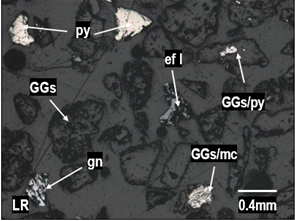

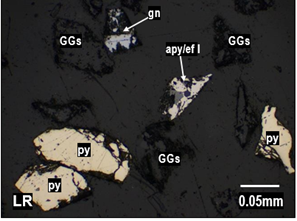

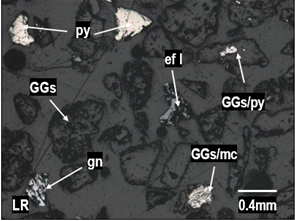

2, 3, and 4 depict the main micrographs of galena from the study adits.

Table 4. Types Of Bonding at Various Particle Size Distribution

Ranges

for the Esmeralda, Orión, and Hércules Adits.

|

Particle size

|

Esmeralda Adit

|

Orión Adit

|

Hércules Adit

|

|

Bonding

|

Vol. (%)

|

Liberation potential

|

Bonding

|

Vol.

(%)

|

Liberation potential

|

Bonding

|

Vol.

(%)

|

Liberation potential

|

|

+100 mesh

|

py/gn

|

0.04

|

Moderately easy

|

gn/sph I

|

0.09

|

Easy

|

|

|

|

|

GGs/gn

|

0.08

|

Moderately easy

|

GGs/gn

|

0.23

|

Very difficult

|

|

|

|

|

GGs/py/gn

|

0.25

|

Moderately difficult

|

apy/gn

|

0.19

|

Very difficult

|

py/gn

|

1.79

|

Easy

|

|

GGs/gn/Fhls

|

0.08

|

Moderately easy

|

py/gn/sph I

|

0.09

|

Moderately easy

|

gn/sph I

|

0.83

|

Moderately easy

|

|

GGs/py/gn/sph I

|

0.08

|

Moderately easy

|

GGs/apy/gn

|

0.09

|

Moderately easy

|

|

|

|

|

|

|

|

GGs/gn/sph I

|

0.19

|

Moderately easy

|

|

|

|

|

<−100, +200] mesh

|

apy/gn

|

0.08

|

Easy

|

gn/sph I

|

0.24

|

Easy

|

|

|

|

|

py/gn

|

0.08

|

Easy

|

apy/gn

|

0.08

|

Easy

|

|

|

|

|

GGs/gn

|

0.08

|

Very difficult to impossible

|

cp/gn

|

0.08

|

Very difficult to impossible

|

gn/sph I,

|

0.02

|

Easy

|

|

gn/Fhls

|

2.00

|

Moderately easy

|

GGs/gn

|

0.16

|

Moderately easy

|

gn/sph II

|

0.16

|

Easy

|

|

GGs/py/gn

|

0.08

|

Moderately difficult

|

GGs/cp/CGRs

|

0.08

|

Moderately easy

|

|

|

|

|

py/apy/gn

|

1.00

|

Very difficult

|

|

|

|

|

|

|

|

<−200, +400] mesh

|

gn/Fhls

|

0.10

|

Moderately difficult

|

|

|

|

|

|

|

|

gn/Pb sulfosalts

|

0.29

|

Very difficult

|

|

|

|

|

|

|

|

gn/sph I

|

0.10

|

Easy

|

gn/sph I

|

0.12

|

Moderately easy

|

sph I/gn

|

0.11

|

Moderately easy

|

|

apy/gn

|

0.19

|

Moderately easy

|

py/gn

|

0.12

|

Moderately easy

|

GGs/apy/gn

|

0.17

|

Moderately easy

|

|

gn/stb

|

0.10

|

Easy

|

apy/gn

|

0.23

|

Impossible

|

|

|

|

|

cp/gn/CGRs

|

0.10

|

Moderately easy

|

|

|

|

|

|

|

|

py/gn/CGRs

|

0.10

|

Moderately easy

|

|

|

|

|

|

|

Note. The table shows the galena forming bonds with other ores

and their liberation potential.

Source: Prepared by the authors.

|

MAIN MICROGRAPHS OF GALENA IN THE STUDY ADITS

|

|

ESMERALDA

|

ORIÓN

|

HÉRCULES

|

|

Figure 2. Liberated grains of gangues (GGs), pyrite (py), galena (gn), mixed

gangue/magnetite (GGs/mt), and pyrite/sphalerite I (py/sphI) found in

particle sizes of +100 mesh. Figure 2. Liberated grains of gangues (GGs), pyrite (py), galena (gn), mixed

gangue/magnetite (GGs/mt), and pyrite/sphalerite I (py/sphI) found in

particle sizes of +100 mesh.

|

Figure 3. Liberated grains of gangues

(GGs), pyrite (py), galena (gn), and arsenopyrite/sphalerite I (apy/sph I) found

in the particle size distribution range of Figure 3. Liberated grains of gangues

(GGs), pyrite (py), galena (gn), and arsenopyrite/sphalerite I (apy/sph I) found

in the particle size distribution range of

<−100, +200] mesh.

|

Figure 4. Liberated grains of pyrite (py),

sphalerite (sph I), galena (gn) and gangues (GGs), binary mixed particles of

gangues with marcasite (GGs/mc) found in particle sizes of +100 mesh. Figure 4. Liberated grains of pyrite (py),

sphalerite (sph I), galena (gn) and gangues (GGs), binary mixed particles of

gangues with marcasite (GGs/mc) found in particle sizes of +100 mesh.

|

Note. The figures show the liberated and interlocked grains in

the study adits.

Source: Prepared by the authors.

Plackett-Burman experimental design for the

Esmeralda, Orión, and Hércules adits

Flotation tests were conducted on representative samples from the three

mine adits under study, focusing on the effects of the reagent blend

(AP-3418/AR-404), AR-242, and the pH of the pulp. The tests evaluated the

following parameters: reagent blend concentrations of 18, 24, and 30 g/t;

AR-242 concentrations of 5, 10, and 15 g/t; and pH values of 10.5, 11.0, and

11.5. In the Esmeralda adit, the highest lead (Pb) recovery was 84.60%, which

was achieved during run order 3. The best grade concentrate achieved was

60.24%, corresponding to run order 6. Additionally, the highest silver (Ag)

recovery was 84.96%, with a head grade of 341.58 oz/t, attained in run order 4.

The results of the total tests for the experimental design of the Esmeralda adit

are detailed in Table 5.

In the Orión adit, the maximum lead (Pb) recovery was 83.73%, achieved in

run order 2, while the highest grade of lead (Pb) concentrate, 61.63%, was

obtained from run order 7. The highest silver (Ag) recovery was 82.50%, achieved

in run order 4, while the best silver (Ag) head grade of 85.35 oz/t was

achieved in run order 3. The experimental design results for the Orión adit are

provided in Table 6.

In the Hércules adit, the best lead (Pb) recovery was 83.79%, as recorded

in run order 9. The highest grade of lead (Pb) concentrate, 56.25%, was

achieved in run order 2. The highest silver (Ag) recovery recorded was 82.57%,

obtained in run order 3, while the best head grade was 63.66 oz/t, noted in run

order 6. The total experimental design tests are summarized in Table 7.

Table 5. Plackett-Burman Experimental Design and Results of the

Metallurgical Tests Conducted at the Esmeralda Adit.

|

Run order

|

pH

|

Reagent blend (AP-3418/AR-404)

|

AR-242

|

pH

|

Reagent blend (AP-3418/AR-404)

|

AR-242

|

Pb recovery (%)

|

Pb head grade (%)

|

Ag recovery (%)

|

Ag head grade (oz/t)

|

|

1

|

1

|

1

|

−1

|

11.5

|

30

|

5

|

83.68

|

57.24

|

84.72

|

297.54

|

|

2

|

1

|

−1

|

−1

|

11.5

|

18

|

5

|

82.00

|

58.66

|

83.79

|

310.64

|

|

3

|

1

|

1

|

1

|

11.5

|

30

|

15

|

84.60

|

56.25

|

84.91

|

326.46

|

|

4

|

0

|

0

|

0

|

11

|

24

|

10

|

83.30

|

56.27

|

84.96

|

341.58

|

|

5

|

0

|

0

|

0

|

11

|

24

|

10

|

83.01

|

56.62

|

84.80

|

339.41

|

|

6

|

−1

|

−1

|

−1

|

10.5

|

18

|

5

|

81.20

|

60.24

|

82.15

|

312.07

|

|

7

|

−1

|

1

|

1

|

10.5

|

30

|

15

|

83.24

|

55.46

|

83.47

|

310.58

|

|

8

|

−1

|

1

|

−1

|

10.5

|

30

|

5

|

82.21

|

59.25

|

81.23

|

295.10

|

|

9

|

−1

|

−1

|

1

|

10.5

|

18

|

15

|

82.36

|

57.78

|

82.06

|

290.00

|

|

10

|

1

|

−1

|

1

|

11.5

|

18

|

15

|

80.77

|

56.80

|

80.82

|

335.07

|

Note. The table presents the operational variables used for

the experimental design.

Source: Prepared by the authors.

Table 6. Plackett-Burman Experimental Design and Results of the

Metallurgical Tests Conducted at the Orión Adit.

|

Run order

|

pH

|

Reagent blend (AP-3418/AR-404)

|

AR-242

|

pH

|

Reagent blend (AP-3418/AR-404)

|

AR-242

|

Pb recovery (%)

|

Pb head grade (%)

|

Ag recovery (%)

|

Ag head grade (oz/t)

|

|

1

|

0

|

0

|

0

|

11

|

24

|

10

|

83.18

|

57.65

|

81.58

|

74.58

|

|

2

|

0

|

0

|

0

|

11

|

24

|

10

|

83.73

|

57.15

|

81.85

|

73.22

|

|

3

|

−1

|

1

|

−1

|

10.5

|

30

|

5

|

81.89

|

61.39

|

81.44

|

85.35

|

|

4

|

−1

|

1

|

1

|

10.5

|

30

|

15

|

82.58

|

59.94

|

82.50

|

84.84

|

|

5

|

1

|

1

|

−1

|

11.5

|

30

|

5

|

82.24

|

58.93

|

81.17

|

77.67

|

|

6

|

−1

|

−1

|

−1

|

10.5

|

18

|

5

|

82.32

|

61.60

|

79.44

|

78.24

|

|

7

|

1

|

−1

|

1

|

11.5

|

18

|

15

|

78.34

|

61.63

|

75.68

|

76.22

|

|

8

|

−1

|

−1

|

1

|

10.5

|

18

|

15

|

83.71

|

59.30

|

81.31

|

77.55

|

|

9

|

1

|

1

|

1

|

11.5

|

30

|

15

|

82.28

|

59.34

|

79.10

|

79.34

|

|

10

|

1

|

−1

|

−1

|

11.5

|

18

|

5

|

78.97

|

60.69

|

78.83

|

76.68

|

Note. The table presents the operational variables used for the

experimental design.

Source: Prepared by the authors.

Table 7. Plackett-Burman Experimental Design and Results of

the Metallurgical Tests Conducted at the Hércules Adit.

|

Run order

|

pH

|

Reagent blend (AP-3418/AR-404)

|

AR-242

|

pH

|

Reagent blend (AP-3418/AR-404)

|

AR-242

|

Pb recovery (%)

|

Pb head grade (%)

|

Ag recovery (%)

|

Ag head grade (oz/t)

|

|

1

|

0

|

0

|

0

|

11

|

24

|

10

|

83.30

|

51.94

|

78.26

|

38.30

|

|

2

|

1

|

−1

|

−1

|

11.5

|

18

|

5

|

82.53

|

56.25

|

79.38

|

36.94

|

|

3

|

−1

|

−1

|

1

|

10.5

|

18

|

15

|

83.29

|

48.11

|

82.57

|

43.38

|

|

4

|

−1

|

1

|

−1

|

10.5

|

30

|

5

|

82.83

|

49.29

|

82.16

|

57.07

|

|

5

|

0

|

0

|

0

|

11

|

24

|

10

|

83.40

|

52.26

|

78.36

|

36.88

|

|

6

|

1

|

1

|

−1

|

11.5

|

30

|

5

|

80.18

|

56.16

|

78.29

|

63.66

|

|

7

|

−1

|

−1

|

−1

|

10.5

|

18

|

5

|

81.31

|

47.17

|

81.82

|

41.29

|

|

8

|

1

|

1

|

1

|

11.5

|

30

|

15

|

82.40

|

54.12

|

80.88

|

62.63

|

|

9

|

−1

|

1

|

1

|

10.5

|

30

|

15

|

83.79

|

48.13

|

80.94

|

55.69

|

|

10

|

1

|

−1

|

1

|

11.5

|

18

|

15

|

84.54

|

54.67

|

80.92

|

37.94

|

Note. The table presents the operational variables used for

the experimental design.

Source: Prepared by the author.

Standardized effects analysis

Table 8 outlines the influence of the variables pH, reagent blend

(AP-3418/AR-404), AR-242, and their interactions on the recovery and

concentrate quality responses for the study adits.

Table 8. Summary of the Interactions of the Main Variables.

|

Adit

|

Response

|

Variables

|

|

Esmeralda

|

Lead (Pb) head grade

|

AR-242

|

|

Lead (Pb) recovery

|

AP-3418/AR-404

|

|

Silver (Ag) head grade

|

pH, (pH – AR-242) interaction

|

|

Silver (Ag) recovery

|

AP-3418/AR-404, pH, (AP-3418/AR-404 – AR-242)

interaction, (pH – AR-242) interaction, (pH – AP-3418/AR-404) interaction

|

|

Orión

|

Lead (Pb) head grade

|

Interaction (pH – AR-242), (pH –

AP-3418/AR-404) interaction, AP-3418/AR-404

|

|

Lead (Pb) recovery

|

Interaction (pH – AR-242), AR-242,

AP-3418/AR-404

|

|

Silver (Ag) head grade

|

AP-3418/AR-404, A, (pH – AP-3418/AR-404)

interaction

|

|

Silver (Ag) recovery

|

pH, AP-3418/AR-404, (pH – AR-242)

interaction

|

|

Hércules

|

Lead (Pb) head grade

|

pH

|

|

Lead (Pb) recovery

|

AR-242, interaction (pH – AP-3418/AR-404)

|

|

Silver (Ag) head grade

|

AP-3418/AR-404

|

|

Silver (Ag) recovery

|

pH, AP-3418/AR-404, (pH – AR-242)

interaction, (pH – AP-3418/AR-404 – AR-242) interaction

|

Note. The table depicts the interactions observed in the

Esmeralda, Orión, and Hércules adits.

Source: prepared by the authors.

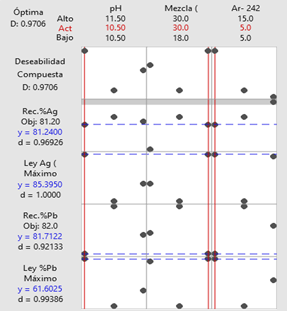

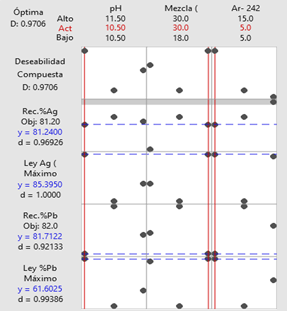

Optimization of flotation parameters for polymetallic ore

The independent variables that most significantly contributed to the

flotation process of the three adits under study were optimized using Minitab

19. For the Esmeralda adit, the optimization results indicated a dosage of 18 g/t of reagent blend, 5 g/t of Ar-242, and a pH of 11.5.

For the Orión adit, the optimization results indicated a dosage of 30 g/t of reagent

blend, 5 g/t of Ar-242, and a pH of 10.5. Lastly, for the Hércules adit, the

optimization results indicated a dosage of 30 g/t of reagent blend, 15 g/t of

Ar-242, and a pH of 11.5. The results and optimization plots for the flotation

of minerals from the Esmeralda, Orión, and Hércules adits can be found in

Figures 5, 6, and 7.

|

ESMERALDA ADIT

|

ORIÓN ADIT

|

HÉRCULES ADIT

|

|

Figure 5. Optimization plot of the

flotation parameters for pit 01.

|

Figure 6. Optimization

plot of the flotation parameters for pit 02. Figure 6. Optimization

plot of the flotation parameters for pit 02.

|

Figure 7. Optimization

plot of the flotation parameters for pit 03. Figure 7. Optimization

plot of the flotation parameters for pit 03.

|

Note. The table presents the optimization plot of the

independent and dependent variables in the three study adits.

Source: Prepared by the authors.

HYPOTHESIS TESTING

The results of the Plackett-Burman experimental design for the Esmeralda adit,

which was developed based on the mineralogical characterization of the adit,

are shown in Table 5. Run order 2 identifies the optimal levels of recovery

and grade of lead-silver concentrate, determined by the dosage of reagents. The

results of test 2 differ from the other runs for this adit in terms of test

conditions, thereby confirming the hypothesis.

For the Orion adit, the experimental design was similarly based on its

mineralogical characterization. The findings indicate that run order 3 achieves

the optimal values for the recovery and grade of the lead-silver concentrate,

which are influenced by the independent variable of reagent dosage. This result

significantly differs from those of the other tests, as illustrated in Table 6,

thus confirming the hypothesis.

Similarly, for the Hercules adit, the development of the experimental

design and selection of reagents for the flotation tests were also based on its

mineralogical characterization. The results from this series of tests

demonstrate that run order 8 yields the optimal values for recovery and grade

of the lead-silver concentrate, as shown in Table 7. These findings differ

significantly from the other runs, further supporting the hypothesis.

DISCUSSION

The results obtained in this research allowed for the optimization of

lead-silver (Pb-Ag) recovery rate by flotation through mineralogical and

metallurgical characterization, as well as the optimal design of the flotation

process of polymetallic ore. The mineralogical characterization revealed that

most valuable particles exhibited a simple intergrowth texture, which proved

beneficial for the concentration process. On the other hand, the experimental

design showed that to enhance metallurgical performance for recovering lead and

silver from the Esmeralda adit, 18 g/t of reagent blend (AP-3418 and AR-404), 5

g/t of AR-242, and an optimal pH of 11.50 were necessary. For the Orion adit,

the optimal parameters included 30 g/t reagent blend (AP-3418 and AR-404), 5

g/t of AR-242, and a pH of 10.50. Similarly, for the Hercules adit, the optimal

parameters were 30 g/t of reagent blend (AP-3418 and AR-404), 15 g/t of AR-242,

and a pH of 11.50.

In comparing the work of Ramos and Orihuela (2017) with this study, which

aimed to evaluate complex polymetallic minerals through flotation metallurgical

tests to obtain copper, lead, and zinc concentrates with satisfactory

recoveries and grades that meet smelting requirements, it was concluded that

the best conditions for copper-lead separation involved a dosage of activated

carbon of 233.3 g/t, 60 g/t of reagent blend BCS, 10 g/t of collector Ap 5100,

and maintaining the pH under natural conditions for 7 minutes. This resulted in

a copper concentrate grade of 25.6% and a lead concentrate grade of 54.3%. In

contrast, this research determined that optimal metallurgical performance in

recovering lead and silver required a reagent blend dosage ranging from 18 to 30

g/t (AP-3418 and AR-404), AR-242 dosages ranging from 5 to 15 g/t, and a pH

level ranging from 10.5 and 11.5, as detailed in Tables 5, 6, and 7.

CONCLUSIONS

The mineralogical characterization of representative

samples from the study adits identified several minerals. In adit 1, the

identified minerals were pyrite, arsenopyrite, galena, chalcopyrite, fahlores,

sphalerite I, magnetite, stibnite, sphalerite II, marcasite, lead sulfosalts,

and pyrrhotite. In adit 2, the minerals found were pyrite, arsenopyrite,

marcasite, galena, chalcopyrite, sphalerite I, sphalerite II, magnetite,

stibnite, hematite, rutile, and fahlores. Finally, in adit 3, the minerals

found were pyrite, arsenopyrite, marcasite, galena, chalcopyrite, pyrrhotite,

sphalerite I, sphalerite II, and rutile. Most of the minerals of interest

exhibited a simple intergrowth texture, while a smaller fraction showed a more

complex intergrowth structure. This complexity can enhance the separation,

flotation, and concentration processes of the minerals of interest.

The standardized analysis of effects in the experimental design allowed

for identifying the interactions of variables (A: pH, B: reagent blend, C:

collector AR-242) that significantly influence the head grade and recovery rate

of lead (Pb) and silver (Ag). Consequently, the parameters for optimizing

metallurgical performance were established as follows: For adit 1, the

recommended dosage is 18 g/t of reagent blend (AP-3418 and AR-404), 5.0 g/t of a

secondary collector AR-242, and a pH of 11.50. For adit 2, the dosage is 30 g/t

of reagent blend (AP-3418 and AR-404), 5.0 g/t of secondary collector AR-242, and

a pH of 10.50. For adit 3, the dosage is 30 g/t of reagent blend (AP-3418 and

AR-404), 15.0 g/t of secondary collector AR-242, and a pH of 11.50.

Operational variables such as particle size, air flow in flotation cells,

and conditioning times contribute to establishing a recovery model and

determining the quality of concentrates from a geometallurgical perspective.

ACKNOWLEDGMENT

We express our gratitude to the Graduate Unit of the School of

Geological, Mining, Metallurgical, and Geographic Engineering at Universidad

Nacional Mayor de San Marcos.

REFERENCES

[1]

Alves, F. E. A. (2014). Caracterização

mineralógica de amostras de Resíduo da Mineração de Chumbo em Boquira (BA) (Degree thesis). Universidade

Federal do Rio de Janeiro, Rio de Janeiro.

https://pantheon.ufrj.br/bitstream/11422/5447/1/ALVES%2c%20F.E.A.pdf

[2]

Aranda Bruno, J. A. (2014). Optimización por

diseño experimental de la flotación de concentrados bulk plomo y plata a nivel

laboratorio en la FIQ. (Degree

thesis). Universidad Nacional del Centro del Perú, Huancayo.

https://repositorio.uncp.edu.pe/bitstream/handle/20.500.12894/3721/Aranda%20Bruno.pdf?sequence=1&isAllowed=y

[3]

Astucuri, V. (1994). Introducción a la

flotación de minerales. Lima N. E.

[4]

Ayllón Meresi, D. E. (2013). Optimización

del proceso de flotación Bulk Plomo-Plata. (Degree

thesis). Universidad Nacional de Ingeniería, Lima.

https://repositorio.uni.edu.pe/handle/20.500.14076/10542

[5]

Bertolino, L., Alves, F., Mendes, J., &

Neumann, R. (2014). Caracterização mineralógica preliminar de amostras do

rejeito da antiga mineração de chumbo em Boquira, Bahia. Comunicações

Geológicas, 101, 965-968. https://www.lneg.pt/wp-content/uploads/2020/03/76_2985_ART_CG14_ESPECIAL_II.pdf

[6]

Bustamante, M. O., Gaviria, A. C., & Restrepo,

O. J. (2008). Notas de clase de la asignatura: Concentración

de minerales. Medellín, Colombia: Universidad Nacional de Colombia.

[7]

Chen, J. (2021). The interaction of flotation

reagents with metal ions in mineral surfaces: A perspective from coordination

chemistry. Minerals Engineering, 171.

https://doi.org/10.1016/j.mineng.2021.107067

[8]

Dou, S., Xu, D., Zhu, Y., & Keenan, R.

(2023). Critical mineral sustainable supply: Challenges and governance. Futures,

146. https://doi.org/10.1016/j.futures.2023.103101

[9]

Elizondo, M., Uribe, A., & Bello, S.

(2021). Chemical stability of xanthates,

dithiophosphinates and hydroxamic acids in aqueous solutions and their

environmental implications. Ecotoxicology and Environmental Safety, 207.

https://doi.org/10.1016/j.ecoenv.2020.111509

[10] Espinoza,

L. A., Iriarte, G., Espinoza, L. O., Gutarra, R., Herrera, M., Zamalloa, J.,

Aramburú, V. S., & Torres, J. A. (2021). Importancia de la mineralogía en

la geometalurgia: aplicación en Perú. Revista del Instituto de investigación

de la Facultad de minas,metalurgia y ciencias geográficas, 24(48), 85-100.

https://doi.org/10.15381/iigeo.v24i48.21707

[11] López

Príncipe, P. H., & Ipanaqué

Nizama, O. S. (2008). Caracterización y optimización de flotación a nivel

laboratorio del mineral de cobre de la minera Candelaria. (Degree thesis). Universidad Nacional Mayor de San Marcos.

https://cybertesis.unmsm.edu.pe/handle/20.500.12672/3272

[12]

Ministerio de Energía y Minas.

(2022). Boletín Estadístico Minero: Por concepto de canon y regalías

mineras, minería genera mayores ingresos para las regiones (Edición N.°

01-2022). Ministerio de Energía y Minas.

https://cdn.www.gob.pe/uploads/document/file/2878178/BEM%2001-2022.pdf.pdf?v=1648163997

[13] Melgarejo,

J. C., Provenza, J. A., Galí, S., & Llovet, X. (2010). Técnicas de

caracterización mineral y su aplicación en exploración y explotación minera. Boletín

de la Sociedad Geológica Mexicana, 62(1), 1-23.

http://www.scielo.org.mx/scielo.php?script=sci_arttext&pid=S1405-33222010000100002&lng=es&tlng=es

[14]

Nassar,

N. T., Graedel, T. E., & Harper, E. M. (2015). By-product

metals are technologically essential but have problematic supply. Science

Advances, 1(3). https://doi.org/10.1126/sciadv.1400180

[15] Ojeda

Escamilla, M. C., Reyes Bahena, J. L., & Aragón Piña, A. (2010, Otober 27-30).

Caracterización mineralógica en la industria minera. Convención Minera

del Bicentenario, Ixtapa, Zihuatanejo, Mexico.

[16] Ramos,

J., & Orihuela, A. (2017). Caracterización y evaluación

de pruebas metalúrgicas de flotación de un mineral complejo polimetálico del

distrito de Palca - Huancavelica.

(Degree thesis). Universidad Nacional Mayor de San Marcos,

Lima. https://alicia.concytec.gob.pe/vufind/Record/UNMS_b2570f1e40152d212efd90f88551c1b6

[17]

Shen, Y., Nagaraj, D. R., Farinato, R., &

Somasundaran, P. (2016). Study of xanthate decomposition in aqueous solutions. Minerals

Engineering, 93, 10-15. https://doi.org/10.1016/j.mineng.2016.04.004

[18]

Song, B., Dong, X., Qiu, X., Hu, Z., &

Wang, Y. (2021). Electronic structure and flotation behavior of Ag-bearing

galena. Journal of Alloys and Compounds, 868. https://doi.org/10.1016/j.jallcom.2021.159105

[19] Taya

Flores, W. H. (2018). Optimización de la flotación polimetálica en la planta

concentradora Mallay. (Degree thesis). Universidad Nacional de San Agustín,

Arequipa.

https://repositorio.unsa.edu.pe/items/f80506e6-7e7f-4c1d-b8c5-b4bb765cb337

[20]

Tercero,

N., Nagaraj, D. R., & Farinato, R. (2019). A

Critical Overview of Dithiophosphinate and Dithiophosphate Interactions with

Base Metal Sulfides and Precious Metals. Mining, Metallurgy &

Exploration, 36, 99-110. https://doi.org/10.1007/s42461-018-0039-1

[21]

Tiu, G., Ghorbani, Y., Jansson, N., &

Wanhainen, C. (2021). Tracking silver in the Lappberget Zn-Pb-Ag-(Cu-Au)

deposit, Garpenberg mine, Sweden: Towards a geometallurgical approach. Minerals

Engineering, 167. https://doi.org/10.1016/j.mineng.2021.106889

[22]

U.S. Geological Survey (2019). Mineral Commodity Summaries 2019.

U.S. Geological Survey. https://doi.org/10.3133/70202434

[23]

Xie, H., Liu, Y., Rao, B., Wu, J., Gao, L.,

Chen, L., & Tian, X. (2021). Selective passivation behavior of galena

surface by sulfuric acid and a novel flotation separation method for

copper-lead sulfide ore without collector and inhibitor. Separation and

Purification Technology, 267.

https://doi.org/https://doi.org/10.1016/j.seppur.2021.118621

[24]

Yekeler, M., & Yekeler, H. (2006). A

density functional study on the efficiencies of 2-mercaptobenzoxazole and its

derivatives as chelating agents in flotation processes. Colloids and

Surfaces A: Physicochemical and Engineering Aspects, 268(1-3), 121-125.

https://doi.org/10.1016/j.colsurfa.2006.03.012

[25]

Yovanovic, A. (2004). Engenharia da

Concentração de Massa por Flotação. Belo Horizonte, MG, Brazil: Modelo

Operacional.

https://www.modelooperacional.com.br/wp-content/uploads/2019/04/Engenharia-da-Concentracao-de-Massa-por-Flotacao.pdf

[26]

Zou, S., Lin, Q., Wang, S., Ma, X., &

Zhong, H. (2022). A novel surfactant O,O'-bis(2-butoxyethyl)

ammonium dithiophosphate: Synthesis, selective flotation and adsorption

mechanism towards galena. Minerals Engineering, 179.

https://doi.org/https://doi.org/10.1016/j.mineng.2022.107466

Authors’ contribution

José David Valverde Díaz (first author): Investigation, funding

acquisition, project administration, and software.

Vidal Sixto Aramburú Rojas (co-author): Conceptualization, data curation,

formal analysis, and resources.

Jorge Alberto Ortiz Barreto (co-author): Investigation, methodology, visualization,

original draft preparation, and writing (review & editing).

Rosa María Tiburcio Alva (co-author): Formal analysis, methodology, supervision,

and validation.

Sharon Elisa Aguilar Zevallos: Investigation and writing (review &

editing).