Revista Industrial Data

26(2): 315-333 (2023)

DOI: https://doi.org/10.15381/idata.v26i2.24008

ISSN: 1560-9146

(Impreso) / ISSN: 1810-9993 (Electrónico)

Prototype Android Application for Electromechanical Dimensioning of

Glass Insulator Strings under IEC-60071 and IEC-60815 (2008) Standards

Fabrizio Armando Millan

Montalvo

Jose Andres Huamani Cornejo

Jose Raul Izquierdo Perez

Christian Edward Rosales Inga

Karla Edita Salazar

Tello

Systems

and Information Technology

Submitted:

17/11/2022 Accepted: 12/04/2023 Published: 20/12/2023

DOI:

https://doi.org/10.15381/idata.v26i2.24008.g20436

ABSTRACT

In this study, a new Android application was

developed to help users accurately determine the dimensioning

of a string insulator through the analysis of the evaluation of two methods

based on IEC-60071 and IEC-60815 (2008) standards. The first method uses equations

from IEC-60815-2 (2008), while the second method considers

parameters such as relative air density and pressure. To ensure reliability, both

methods are evaluated: the first through the creepage factor to determine if

the chosen profile is suitable, and the second through lightning and

switching critical flashover voltages to avoid insulator

flashover. Tests were carried out using data from real projects, and those

results were compared with the results obtained from the application. The

number of string insulators obtained from the tests was exactly the same as the

number obtained from the application, except in two cases. Of the three

evaluations, all cases complied satisfactorily with at least two tests.

Keywords: insulator, application, creepage distance, correction

factor, dimensioning.

INTRODUCTION

Transmission and distribution lines are the

means of transport for electrical energy. They are mechanically fastened to

insulator strings to prevent the structure from being energized. For this

reason, proper dimensioning of the string is required. However, the calculation

is challenging for both engineering students and designers on real projects, as

different environmental, mechanical, and regulatory factors are considered. In

addition, human error is possible. Therefore, it is necessary to incorporate all

these factors into an interface that allows direct dimensioning through data

entry and selection.

The objective of this study is to develop the

correct calculation sequence for suspension insulator strings and based on

that, create a prototype Android application to select suspended glass

insulator strings according to International Electrotechnical Commission

standard 60815 (IEC, 2008a, 2008b) and 60071-2 (IEC, 1996) in order to provide

a tool to the electrical engineering community that can be used anywhere to

size the insulator string and also verify if existing strings are adequate.

The contribution of this article to scientific

knowledge is to provide a tool that can be used by engineers in projects and by

students in their professional academic development through the comparison of

their calculations with the results of the application. This contribution is

novel because it is an easy-to-use Android application with results that verify

its reliability.

Calculation and Selection Method

The calculations for the dimensioning of the insulator string are

made so that they meet the necessary requirements for the correct operation of

the transmission line. According to Orellana and Poma (2014), the requirements

consist of having high dielectric strength to avoid flashovers between the

conductor and the support, as well as decreasing the creepage current between

the insulator and the support, even in unfavorable conditions due to weather.

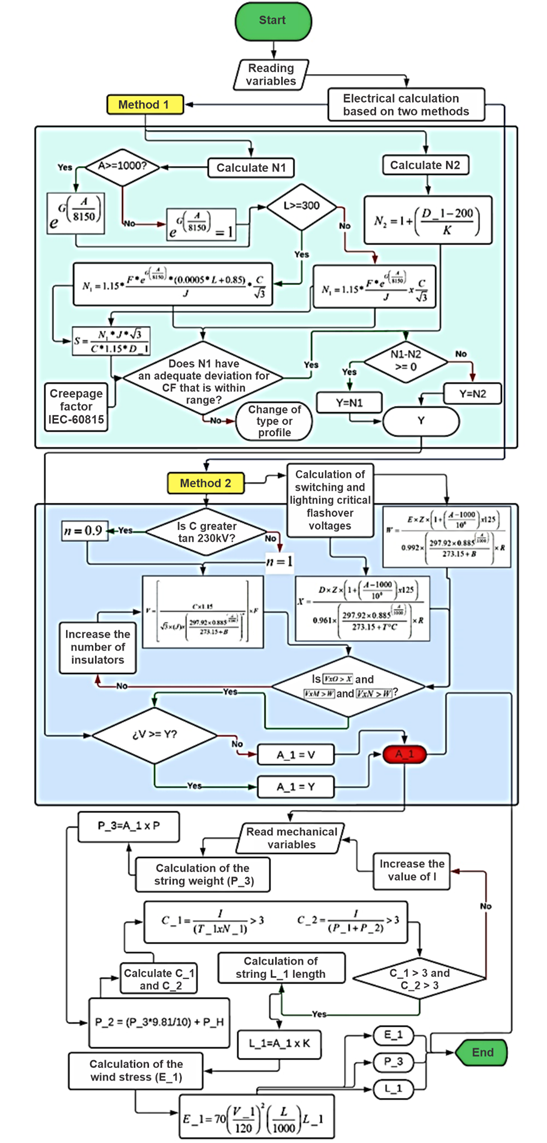

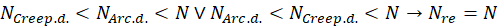

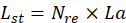

The application flowchart (Figure 2) was structured based on

the development of mathematical expressions that make it possible to obtain

desired results from manually entered data and data selected from the database

extracted from the VERESCENCE (2019) and Sediver (2018) catalogs.

Electrical Calculation

Parameters affecting the electrical calculation

of the glass insulator string were considered. Therefore, the number of insulators obtained must support the

conditions given by the user. For this reason, there will be two calculation

methods. The first is based entirely on the updated IEC-60815-2 standard (IEC,

2008b). The second method determines the result considering pressure and

relative air density. It should be noted that both the first and the second

method will use the contamination levels shown in Table 1, where the creepage distance

according to each pollution level is presented.

Table 1.

Pollution Levels - Reference Unified Specific

Creepage Distance (RUSCD).

|

Pollution Level

|

Basic RUSCD (mm/kV)

|

|

Very light

|

22.0 mm/kV

|

|

Light

|

27.8 mm/kV

|

|

Medium

|

34.7 mm/kV

|

|

Heavy

|

43.3 mm/kV

|

|

Very heavy

|

53.7 mm/kV

|

Source: RUSCD pollution

level parameter based on the pollution severity of the area. (IEC, 2008b).

Method 1: Number of Insulators Based on Creepage and

Arcing Distance

In this method, the mathematical equations found in the updated

standard mentioned above will be shown. Also, the data to be entered in the

application will be shown.

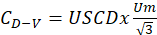

A.

Creepage distance at maximum

operating voltage according to IEC-60815-2 standard (IEC, 2008b):

(1)

(1)

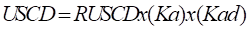

The mathematical expression of USCD is:

(2)

(2)

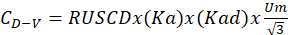

Now, from (1) and (2) the

following is obtained:

(3)

(3)

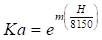

B. Altitude correction factor

Due to the influence of air pressure and density variation at

higher altitudes, which affects operating voltage, IEC-60815-2 standard (IEC,

2008b) mentions that an altitude correction factor must be applied, in

accordance with Díaz and Narváez (2015). This factor is shown in the following

equation (IEC-60071-2, 1996):

(4)

(4)

C.

Correction factor for insulator

average diameter

The IEC-60815-2 standard (IEC, 2008b) also considers a correction

factor based on the insulator diameter. In this sense, there are two conditions

defined by expressions (5) and (6).

(5)

(5)

(6)

(6)

D.

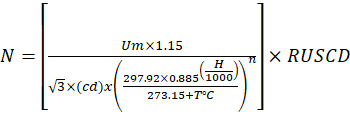

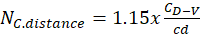

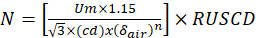

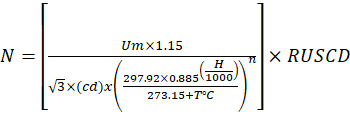

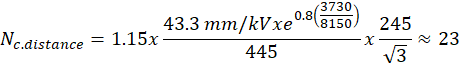

Number of insulators based on the

creepage distance

The following equation (7) considers the phase-to-earth creepage

distance, as specified in the IEC-60815-2 standard (IEC, 2008b). RUSCD only

considers phase-to-earth voltage, not line-to-line as in the previous version

of the standard.

(7)

(7)

It is worth noting the

following:

= Safety factor to avoid flashover in insulators

= Safety factor to avoid flashover in insulators

Number of insulators based on creepage distance

To obtain a complete mathematical expression, the equations

presented above will be joined. The correction factors  and

and  will be placed in expanded form, therefore two final equations are

displayed for the calculation of the number of insulators of method 1, which

will depend on the condition of the diameter of the insulator, therefore the

equations are as follows:

will be placed in expanded form, therefore two final equations are

displayed for the calculation of the number of insulators of method 1, which

will depend on the condition of the diameter of the insulator, therefore the

equations are as follows:

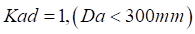

- If the diameter is less than 300 mm

(8)

(8)

- If the diameter is greater than or equal to 300 mm

(9)

(9)

It should be considered that  will be greater than 1 when the

altitude is greater than 1000 m.a.s.l., otherwise, the value of the unit will

be considered.

will be greater than 1 when the

altitude is greater than 1000 m.a.s.l., otherwise, the value of the unit will

be considered.

Equations (8) and (9) will be used in the application by entering

and selecting data, which are mentioned below.

Data to be selected:

-

: Reference Unified Specific Creepage Distance (mm/kV)

: Reference Unified Specific Creepage Distance (mm/kV)

-

: 0.5 (normal), 0.8 (anti-fog)

or 1 (spherical or aerodynamic) according to IEC-60071-2 (1996)

: 0.5 (normal), 0.8 (anti-fog)

or 1 (spherical or aerodynamic) according to IEC-60071-2 (1996)

-  :

maximum operating voltage

:

maximum operating voltage

-  : creepage distance of the insulator (catalog)

: creepage distance of the insulator (catalog)

-

: average insulator diameter (nominal diameter if the insulator

does not have different diameters)

: average insulator diameter (nominal diameter if the insulator

does not have different diameters)

Data to enter:

-

: height above sea level (m.a.s.l.)

: height above sea level (m.a.s.l.)

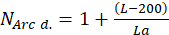

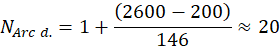

Number of insulators based on arcing distance

The choice of the number of insulators must be adequate so that

the length of the complete insulator string is greater or equal to the critical

phase-to-ground distance. In this sense, the calculation of the minimum number

of insulators is done using equation (10).

(10)

(10)

While the vertical spacing “ ” is catalog data, “

” is catalog data, “ ” is the critical phase-to-earth distance that relates to the

IEC-60815-2 creepage factor (IEC, 2008b). This distance will be given by table

A-1 of IEC-60071-2 (1996).

” is the critical phase-to-earth distance that relates to the

IEC-60815-2 creepage factor (IEC, 2008b). This distance will be given by table

A-1 of IEC-60071-2 (1996).

Data to be selected:

: insulator vertical spacing (mm)

: insulator vertical spacing (mm)

: critical phase-to-earth distance (mm)

: critical phase-to-earth distance (mm)

Evaluation of method 1 based on the creepage factor

In order to determine whether the choice of the insulator string

profile has been optimal, the present evaluation, based on the creepage factor,

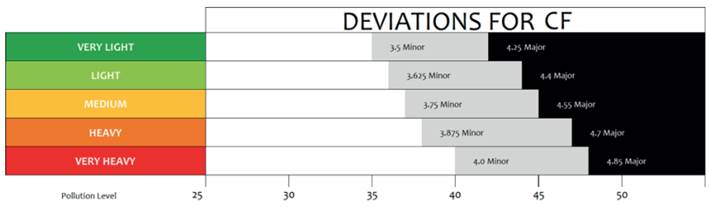

is used and is calculated with the following equation (11):

(11)

(11)

Where:

: total nominal creepage distance of the insulator

: total nominal creepage distance of the insulator

: arcing distance of the insulator (critical distance)

: arcing distance of the insulator (critical distance)

Although these variables are different from the ones used in the

previous equations, they have the same meaning:

(12)

(12)

(13)

(13)

(14)

(14)

It should be noted that  is the number of insulators resulting from method 1.

is the number of insulators resulting from method 1.

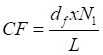

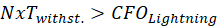

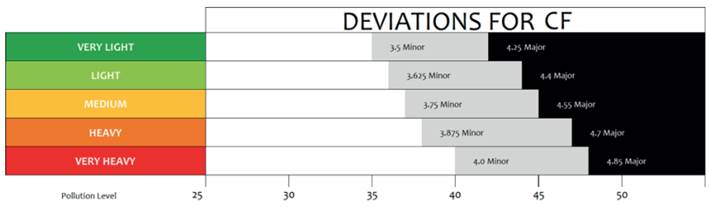

The CF is useful to determine the suitability of the profile, as

shown in Figure 1, where the CF value must be kept in the white zone. If the CF

value moves to the gray or black zone, an insulator string with a different

profile is selected.

Figure 1. Deviations for the creepage

factor (CF) according to each pollution level.

Source: Adapted from Deviations for FC

from IEC 60815-1. (IEC, 2008a).

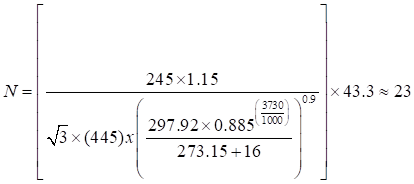

Method 2: Number of isolators by

pressure and relative air density

In this section, the calculation for the number of insulators will

be determined considering the relative air density (with pressure and

temperature), where A, B, and C are based on Portero (2019).

Equation (18) will be used in the application, where the data to

be entered and selected will be shown. In addition, the correction factors to

be used will be shown based on tables.

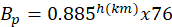

A. Barometric pressure

(cm/hg) (15)

(cm/hg) (15)

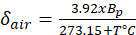

B. Relative air density

(16)

(16)

C. Number of insulators with maximum voltage ( )

)

(17)

(17)

D. Precipitacion correction factor ( )

)

Table 2 shows a correction factor according to precipitation. This

correction factor is added to the equations in the form of multiplication.

Table 2.

Precipitation Correction Factor.

|

Rainfall Intensity

|

Correction Factor

|

|

0.00 mm/min

|

1.00

|

|

1.00 mm/min

|

0.95

|

|

1.27 mm/min

|

0.83

|

|

2.50 mm/min

|

0.77

|

|

3.80 mm/min

|

0.73

|

|

5.10 mm/min

|

0.71

|

|

6.30 mm/min

|

0.68

|

Source: Taken from

Cotto (2021).

E. Humidity correction factor ( )

)

The depends on the relative humidity and temperature. For a frequency

of 60hz, a double-entry table (Table 3) was made using two curve graphs to

obtain the value of the

depends on the relative humidity and temperature. For a frequency

of 60hz, a double-entry table (Table 3) was made using two curve graphs to

obtain the value of the , which makes it an important database in the development of the application.

, which makes it an important database in the development of the application.

Table 3.

Humidity Correction Factor.

|

°C

|

Relative Humidity

|

|

10%

|

20%

|

30%

|

40%

|

50%

|

60%

|

70%

|

80%

|

90%

|

100%

|

|

0

|

1.14492694

|

1.14089224

|

1.11979946

|

1.12015942

|

1.11255994

|

1.10714298

|

1.09736524

|

1.09417581

|

1.08752743

|

1.07666906

|

|

1

|

1.14363001

|

1.13861078

|

1.11910865

|

1.1176695

|

1.10984326

|

1.10362938

|

1.09381732

|

1.08954026

|

1.08258559

|

1.07191786

|

|

2

|

1.14239911

|

1.13641712

|

1.11828013

|

1.11515852

|

1.10703346

|

1.10005624

|

1.09014831

|

1.08484951

|

1.07755023

|

1.06699671

|

|

3

|

1.14122649

|

1.13430128

|

1.11730835

|

1.11260943

|

1.10411497

|

1.0964082

|

1.08634458

|

1.0800814

|

1.07240115

|

1.06188822

|

|

4

|

1.14010448

|

1.13225343

|

1.11618792

|

1.1100055

|

1.10107265

|

1.09267041

|

1.08239315

|

1.07521476

|

1.06711926

|

1.0565763

|

|

5

|

1.13902548

|

1.13026391

|

1.1149136

|

1.10733036

|

1.09789186

|

1.08882854

|

1.07828165

|

1.07022945

|

1.06168665

|

1.05104624

|

|

6

|

1.13798196

|

1.12832319

|

1.11348036

|

1.10456801

|

1.09455847

|

1.0848688

|

1.07399846

|

1.06510644

|

1.0560866

|

1.04528481

|

|

7

|

1.13696643

|

1.12642187

|

1.11188335

|

1.10170284

|

1.09105893

|

1.08077819

|

1.0695327

|

1.05982785

|

1.05030405

|

1.03928037

|

|

8

|

1.13597148

|

1.1245507

|

1.11011794

|

1.09871966

|

1.0873803

|

1.07654408

|

1.06487433

|

1.05437706

|

1.04432492

|

1.033023

|

|

9

|

1.13498975

|

1.12270052

|

1.10817974

|

1.09560378

|

1.08351032

|

1.07215474

|

1.06001419

|

1.04873875

|

1.03813698

|

1.02650461

|

|

10

|

1.1340139

|

1.12086232

|

1.10606462

|

1.09234099

|

1.07943749

|

1.06759911

|

1.0549440

|

1.04289907

|

1.03172956

|

1.01971908

|

|

11

|

1.13303667

|

1.1190272

|

1.10376871

|

1.08891763

|

1.0751511

|

1.0628669

|

1.04965675

|

1.03684566

|

1.02509375

|

1.01266234

|

|

12

|

1.13205085

|

1.11718635

|

1.10128843

|

1.08532065

|

1.07064128

|

1.05794894

|

1.04414613

|

1.03056782

|

1.01822248

|

1.00533254

|

|

13

|

1.13104926

|

1.11533112

|

1.09862051

|

1.08153768

|

1.06589913

|

1.05283655

|

1.03840722

|

1.02405656

|

1.01111068

|

0.99773016

|

|

14

|

1.13002479

|

1.11345295

|

1.09576203

|

1.07755704

|

1.06091674

|

1.04752233

|

1.03243627

|

1.01730476

|

1.00375537

|

0.98985811

|

|

15

|

1.12897036

|

1.11154341

|

1.09271038

|

1.07336782

|

1.05568729

|

1.04199982

|

1.02623082

|

1.01030728

|

0.99615574

|

0.98172183

|

|

16

|

1.12787898

|

1.1095942

|

1.08946333

|

1.06895997

|

1.0502051

|

1.0362637

|

1.01978974

|

1.00306105

|

0.98831332

|

0.97332943

|

|

17

|

1.12674369

|

1.10759714

|

1.08601906

|

1.06432434

|

1.04446573

|

1.03030981

|

1.01311334

|

0.9955652

|

0.98023203

|

0.96469176

|

|

18

|

1.12555762

|

1.10554421

|

1.08237611

|

1.05945278

|

1.0384660

|

1.02413522

|

1.00620342

|

0.98782116

|

0.9719183

|

0.95582247

|

|

19

|

1.12431396

|

1.10342754

|

1.07853347

|

1.05433816

|

1.03220427

|

1.01773833

|

0.99906331

|

0.97983279

|

0.96338118

|

0.94673811

|

|

20

|

1.12300599

|

1.10123939

|

1.07449057

|

1.0489744

|

1.02568012

|

1.01111889

|

0.9916979

|

0.97160645

|

0.95463235

|

0.93745811

|

|

21

|

1.12162706

|

1.09897223

|

1.07024729

|

1.04335697

|

1.01889479

|

1.00427808

|

0.98411399

|

0.9631511

|

0.9456862

|

0.9280048

|

|

22

|

1.12017064

|

1.0966186

|

1.06580399

|

1.0374821

|

1.01185111

|

0.99721858

|

0.97631971

|

0.95447841

|

0.93656014

|

0.91840374

|

|

23

|

1.11863028

|

1.09417159

|

1.06116153

|

1.03134771

|

1.00455353

|

0.9899446

|

0.96832519

|

0.9456027

|

0.92727399

|

0.9086829

|

|

24

|

1.11699967

|

1.09162398

|

1.05632127

|

1.02495304

|

0.9970082

|

0.9824620

|

0.96014227

|

0.93654131

|

0.91785063

|

0.89887339

|

|

25

|

1.11527261

|

1.08896914

|

1.0512851

|

1.01829885

|

0.98922325

|

0.97477828

|

0.95178461

|

0.92731409

|

0.90831567

|

0.8890089

|

|

26

|

1.11344304

|

1.0862005

|

1.04605547

|

1.01138745

|

0.98120829

|

0.9669025

|

0.9432676

|

0.91794391

|

0.8986974

|

0.87912593

|

|

27

|

1.11150506

|

1.08331202

|

1.04063536

|

1.00422278

|

0.9729750

|

0.9588457

|

0.9346088

|

0.9084563

|

0.8890269

|

0.86926298

|

|

28

|

1.10945292

|

1.0802975

|

1.03502833

|

0.9968104

|

0.9645370

|

0.95062057

|

0.9258270

|

0.8988799

|

0.87933753

|

0.8594609

|

|

29

|

1.10728106

|

1.07715161

|

1.02923853

|

0.98915794

|

0.9559098

|

0.94224136

|

0.91694335

|

0.8892454

|

0.86966511

|

0.84976232

|

|

30

|

1.10498412

|

1.0738687

|

1.02327069

|

0.98127434

|

0.94711067

|

0.93372434

|

0.9079803

|

0.8795866

|

0.8600475

|

0.84021127

|

|

31

|

1.10255692

|

1.0704440

|

1.01713015

|

0.9731707

|

0.9381589

|

0.92508747

|

0.8989622

|

0.8699393

|

0.8505247

|

0.83085283

|

|

32

|

1.0999945

|

1.0668728

|

1.01082287

|

0.9648599

|

0.9290759

|

0.91635045

|

0.8899150

|

0.8603416

|

0.84113776

|

0.82173254

|

|

33

|

1.0972922

|

1.06315096

|

1.00435539

|

0.9563568

|

0.91988473

|

0.9075346

|

0.8808661

|

0.8508334

|

0.83192914

|

0.81289585

|

|

34

|

1.0944456

|

1.05927453

|

0.9977349

|

0.9476782

|

0.91061016

|

0.8986632

|

0.87184425

|

0.84145628

|

0.82294194

|

0.80438741

|

|

35

|

1.0914504

|

1.05524017

|

0.9909692

|

0.9388425

|

0.90127893

|

0.8897607

|

0.86287941

|

0.83225274

|

0.81421932

|

0.79625034

|

Source:

Adapted with AutoCAD and Excel from the “Dry Blub Temperature - °C” chart and

“Absolute Humidity – g/m3” charts of LaForest (1982).

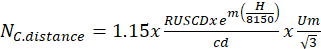

Equation for the number of insulators based on

pressure and relative air density

Equation (18), which will be used in the app, allows finding the

number of insulators based on maximum voltage.

(18)

(18)

Where:

- Data to select:

-

: maximum voltage in kV, according to IEC 60071-1 (IEC, 1993)

: maximum voltage in kV, according to IEC 60071-1 (IEC, 1993)

-

: Reference Unified Specific Creepage Distance (mm/kV) –

IEC-60815-2 (IEC, 2008b)

: Reference Unified Specific Creepage Distance (mm/kV) –

IEC-60815-2 (IEC, 2008b)

-  : creepage distance of the insulator (catalog)

: creepage distance of the insulator (catalog)

-

: If

: If  kV, n = 1; if

kV, n = 1; if  kV, n = 0.9

kV, n = 0.9

- Data to enter:

-

: ambient

temperature

: ambient

temperature

-

: height above sea level (m.a.s.l.)

: height above sea level (m.a.s.l.)

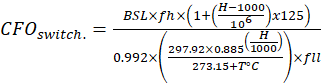

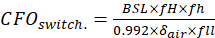

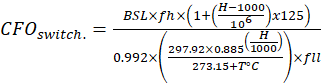

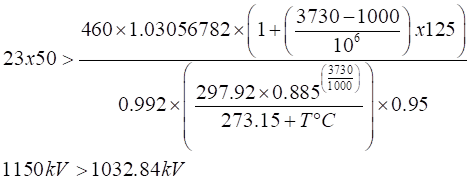

Evaluation of the number of

insulators based on switching critical flashover voltage (CFO switch.)

The number of insulators to be calculated in method 2 must be

adequate to withstand the switching critical

flashover voltage. For this calculation, the

following equation will be used, based on Mendoza et al. (2013), which

considers climatic factors such as rain and humidity.

(19)

(19)

The altitude correction factor  , as well as

, as well as  , will be greater than 1 when the altitude is greater than 1000 m.a.s.l.

Otherwise, the value of the unit will be considered.

, will be greater than 1 when the altitude is greater than 1000 m.a.s.l.

Otherwise, the value of the unit will be considered.

For direct data entry as in the previous equations, the equation

will be defined as follows:

(20)

(20)

For equation (20), the

following will be considered:

- Data to be selected:

-

: basic switching impulse insulation level, according to standard

IEC-60071-1 (IEC, 1993)

: basic switching impulse insulation level, according to standard

IEC-60071-1 (IEC, 1993)

-

: humidity

correction factor

: humidity

correction factor

-

: precipitation

correction factor

: precipitation

correction factor

- Data to be entered:

-

: height above sea level (m.a.s.l.)

: height above sea level (m.a.s.l.)

-

: ambient

temperature

: ambient

temperature

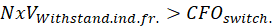

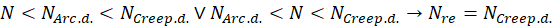

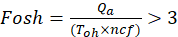

The switching critical flashover voltage must be less than the voltage that the insulator string will withstand.

Therefore, the following condition is proposed, which will be used for the

evaluation of method 2:

(21)

(21)

Where the data to be selected will be:

: withstand voltage at industrial frequency (catalog)

: withstand voltage at industrial frequency (catalog)

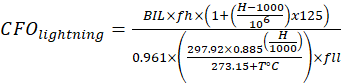

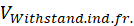

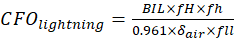

Evaluation of the number of insulators based on

lightning critical flashover voltage (CFO lightning).

In the same way as in the previous evaluation, the following

equation based on Mendoza et al. (2013) will be used. This equation will also

consider climatic factors.

(22)

(22)

The altitude correction factor , as well as

, as well as  , will be greater than 1 when the altitude is greater than 1000

m.a.s.l. Otherwise, the value of the unit will be considered.

, will be greater than 1 when the altitude is greater than 1000

m.a.s.l. Otherwise, the value of the unit will be considered.

For direct data entry as in the previous equations, the equation

will be defined as follows:

(23)

(23)

For equation (23), the

following will be considered:

- Data to be selected:

-

: basic impulse insulation

level, which is the lightning impulse voltage according

to standard IEC-60071-1 (IEC, 1993)

: basic impulse insulation

level, which is the lightning impulse voltage according

to standard IEC-60071-1 (IEC, 1993)

-

: humidity

correction factor

: humidity

correction factor

-

: precipitation

correction factor

: precipitation

correction factor

- Data to be entered:

-

: height above sea level (m.a.s.l.)

: height above sea level (m.a.s.l.)

-

: ambient

temperature

: ambient

temperature

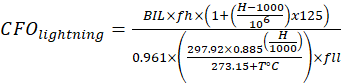

The lightning critical

flashover voltage must be less than the

voltage that the insulator string will withstand. Therefore, the following

condition is proposed, which will be used for the evaluation of method 2:

(24)

(24)

Where the data to be selected will be:

: withstand voltage at industrial frequency (catalog)

: withstand voltage at industrial frequency (catalog)

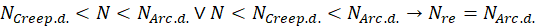

Resulting number of insulators

Based on the previous results, the resulting number of insulators

will be the largest of the three numbers obtained, which have had to pass the

evaluations shown, mathematically the final result can be expressed as follows.

(25)

(25)

(26)

(26)

(27)

(27)

Where:

: number of insulators resulting from the calculation

: number of insulators resulting from the calculation

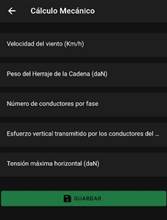

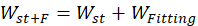

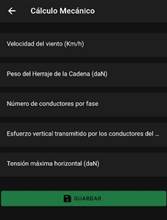

Mechanical calculation

For the mechanical calculation, the equations used by the

application to calculate and select insulators, based on López (2018) and De la

Fuente (2016), will be shown. Therefore, the accessory that mechanically joins

the insulators with the transmission lines,

called a fitting, must be taken into account. The weight of the insulator

string and the fittings will be calculated

through the following ratio:

(28)

(28)

(29)

(29)

Where:

-

Wst: string weight (daN)

-

Nre: number of

insulators in the resulting string

-

Wst+F: Weight of the

insulator string plus fitting (daN)

- Data to be selected:

-

Mins: mass of an

insulator (kg)

- Data to be entered:

-

WFitting: fitting weight (daN)

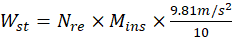

For the mechanical calculation, the factor of safety for failure

of glass insulators Fos must be greater than 3. The insulator must withstand

the normal loads acting on it.

(30)

(30)

Where:

-

Fosv: factor of safety for failure

of insulators under normal loads

- Data to be selected:

-

Qa: breaking load of the

insulator (daN)

- Data to be entered:

-

Pv: vertical stress

transmitted by the conductors to the insulator (daN)

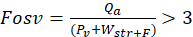

Likewise, the insulator withstands abnormal loads that are found

by means of the following expression:

(31)

(31)

Where:

-

Fosh: factor of safety for failure

of insulators under abnormal loads

- Data to be selected:

-

Qa: failing load of the

insulator (daN)

- Data to be entered:

-

Toh: maximum horizontal

tension under the most unfavorable conditions (daN)

-

ncf: number of

conductors per phase (daN)

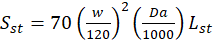

Following this, the string length will be calculated with the

following expression:

(32)

(32)

Where:

-

Lst: string length

(mm)

-

Nre: number of

insulators of the resulting string (number obtained from calculations)

-

La: length of insulator or

spacing (mm)

Finally, it gives the following expression for the wind

stress generated on the insulator string:

(33)

(33)

Where:

-

Sst: wind stress on

the insulator string (daN)

-

Lst: length of

string (mm)

Data to be selected:

-

Da: maximum

diameter of the insulator (mm)

Data to be entered:

-

W: wind speed (Km/h)

Selecting the insulator profile

The considerations on the items 9.1. 9.2 and 9.3 of the standard

IEC-60815-1 (IEC, 2008a) must be taken into account when selecting the

insulator profile. The profiles are the following:

Standard: Used in lines

whose pollution is light or medium.

Anti-fog: Used in areas with

medium to heavy pollution.

Spherical: Similar to an open or aerodynamic profile.

Open or aerodynamic: It has a flat area, which is

very useful in desert areas since the wind cleans the surface of the insulator.

Testing the app

To determine the reliability of the application based on a real

situation, different data extracted from calculation memories of real and

completed projects will be used as a reference, as shown in Table 4. The table

also shows the number of insulators resulting from these calculation memories.

Table 4. Data from

Real Projects.

|

TESTS

|

1

|

2

|

3

|

4

|

5

|

6

|

|

Transmission Line 500 kV

La Niña – Piura Nueva

|

Transmission Line 2 x 220

kV Piura Nueva – Piura Oeste

|

Sub-Station Friaspata

|

Sub-transmission

line to 69 kV Songa

|

Transmission

Line 220 kV Reus – Tarragona

|

Transmission Line 220 kV

Reque – Nueva Carhuaquero

|

|

T (°C)

|

30

|

30

|

16

|

20

|

-

|

-

|

|

Relative humidity (%)

|

75

|

75

|

80

|

80

|

-

|

-

|

|

m.a.s.l.

|

39

|

39

|

3730

|

6

|

-

|

-

|

|

BIL (kV)

|

1550

|

1050

|

1300

|

325

|

1050

|

1050

|

|

BSL (kV)

|

1175

|

460

|

460

|

140

|

460

|

460

|

|

Umax (kV)

|

550

|

245

|

245

|

72.5

|

245

|

245

|

|

Spacing (mm)

|

159

|

146

|

146

|

146

|

170

|

146

|

|

Diameter (mm)

|

330

|

330

|

280

|

254

|

320

|

280

|

|

Creepage distance (mm)

|

620

|

545

|

445

|

290

|

530

|

445

|

|

Pollution level

|

Heavy

|

Heavy

|

Heavy

|

Heavy

|

Very heavy

|

Very heavy

|

|

Number of insulators (calculation memory)

|

28

|

14

|

23

|

5

|

15

|

18

|

Source: Data extracted

from Comité de Operación Económica del Sistema Interconectado Nacional (COES,

2016a, 2016b), SIEMENS (2016), Orellana and

Cevallos (2019), COES (2018), and Olives (2016).

Hypotheses

1.

The resulting number of

insulators coincides in at least 90% with the results of the calculation

memories.

2.

At least two out of the three evaluations of the

calculation methods will result in the term “Acceptable” that will be shown in

the app.

METHODOLOGY

Objective and Justification

This work was carried out with the objective of

optimizing the dimensioning of glass insulator strings by means of a prototype

of an Android application with a didactic interface for academic and

professional use. The choice of an application is based on the practicality it

offers, since users can download it and access it from their cell phones.

Initially, the development of the calculation was made in Excel, however, the

scope of the prototype is greater if it is used on a cellphone, which functions

as a computer, which greatly increases its accessibility.

Development

The development of the app was based on the standards

mentioned before and environmental factors were taken into consideration. For

this reason, two calculation methods that complemented each other were

developed to give a better result. The calculation evaluations were developed

together and fulfill the objective of providing knowledge about the

acceptability of the type of insulator and its characteristics.

Obtaining the Table “Humidity Correction Factor”

AutoCAD and Excel were used to approximate two

tables in order to obtain the humidity correction factor. In this way it was

possible to obtain the curves of the tables and create a double-entry table to

find the humidity correction factor. This value is extracted from crossing the

relative humidity row and the temperature column of Table 3.

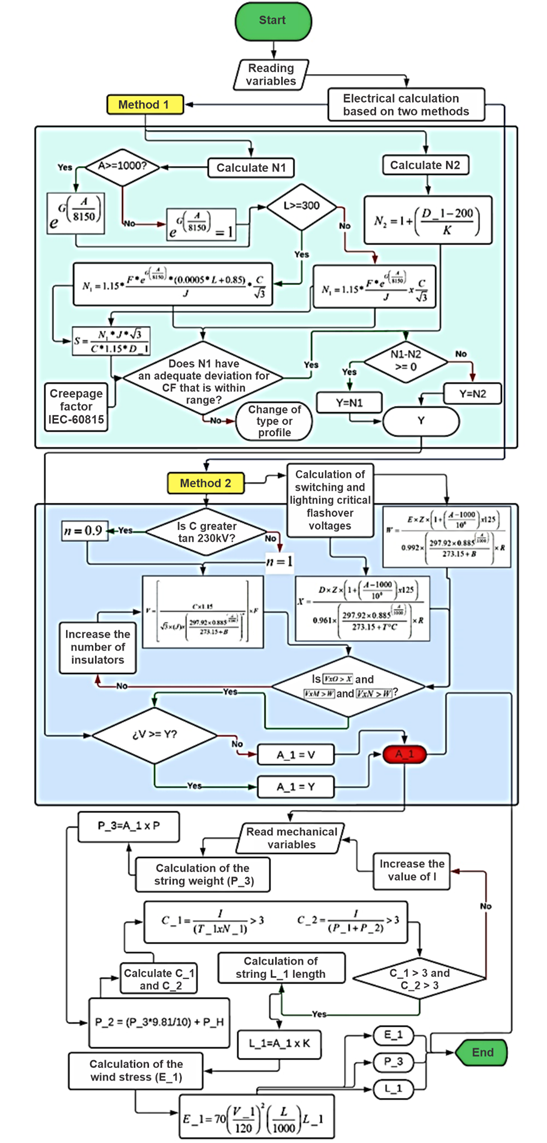

Order of the Calculation Process

Once the calculation base was obtained, the

flowchart shown in Figure 2 was developed. This flowchart is the visual

representation of the operation made by the Android app, which was developed

with a database uploaded to the cloud. Finally, the product obtained is an

application that generates a report of the calculations.

Figure 2. Flowchart for the application.

Source: Prepared by the authors using Lucid.app.

The flowchart shown contains input and output

variables that can be seen in Table 5, where the meaning of each variable can

be found.

Table 5. Variables

Declared on the Flowchart.

|

Input and Output Variables

|

Variables’ Meaning

|

|

A

|

Altitude (m.a.s.l.)

|

|

B

|

Temperature (°C)

|

|

C

|

Maximum voltage (kV)

|

|

D

|

Basic insulation level (kV)

|

|

D_1

|

Critical

distance (mm)

|

|

E

|

Basic switching impulse insulation level (kV)

|

|

F

|

Pollution

level (mm/kV)

|

|

N_1

|

Number of conductors per phase

|

|

T_1

|

Maximum

horizontal tension (daN)

|

|

G

|

Profile or type of insulator

|

|

H

|

Insulator

code

|

|

I

|

Failing

load (daN)

|

|

J

|

Creepage

distance (mm)

|

|

K

|

Spacing

(mm)

|

|

L

|

Diameter

(mm)

|

|

M

|

FT-dry (kV)

|

|

N

|

FT-precipitation (kV)

|

|

O

|

FT-lightning (kV)

|

|

P

|

Insulator

mass (kg)

|

|

Q

|

Relative

humidity

|

|

R

|

Precipitation

correction factor

|

|

P_H

|

Fitting

weight (daN)

|

|

Z

|

Humidity

correction factor

|

|

C_1

|

Safety coefficient to the breakage of the insulators with abnormal

loads.

|

|

P_1

|

Factor of safety for failure of insulators under abnormal loads (daN)

|

|

T_1

|

Maximum

horizontal tension (daN)

|

|

P_2

|

Weight of the insulator string and fitting (daN)

|

|

C_2

|

Factor of safety for failure of insulators under normal loads (daN)

|

|

L_1

|

Length of insulator string (mm)

|

|

P_3

|

Mass of the insulator string (kg)

|

|

E_1

|

Wind stress on the string (daN)

|

|

V_1

|

Wind speed

(km/h)

|

Source: Prepared by

the authors.

App Development and User Interface

The Android application was developed in Java

language using Android default libraries and control structures, which are

mostly conditional and loops. In this way the equations were placed and

connected following the structure of Figure 2. In addition, the database

containing tables and insulator data was uploaded to the cloud using the platform

Firebase.

The equations previously shown for the dimensioning of the

insulator string will be entered into the application together with the

database containing the necessary parameters for the selection. Figures 3, 4,

5, 6 and 7 show the user interface where the data will be entered and selected

in the application. This will be done in each of the fields shown, which have

boxes, drop-down lists and buttons for easy use. The name of the application

will be “Untels Insulator”.

Figure 3. Main User Interface.

Source: Prepared by

the authors (screenshot).

Figure 4. User Interface for Geographic Data.

Source: Prepared by

the authors (screenshot).

Figure 5. User

Interface for Transmission Line Data.

Source: Prepared by

the authors (screenshot).

Figure 6. User

Interface for Insulator Data.

Source: Prepared by

the authors (screenshot).

Figure 7. User Interface for Mechanical Calculation.

Source: Prepared by

the authors (screenshot).

Limitations of the Application Prototype

During the development and implementation of the

application, certain limitations were found. These are mainly related to the

database since there are only two glass insulator catalogs. Also, an option for

manual data entry has not yet been developed since it considerably increases

the complexity of the programming. It is worth mentioning that the application

is also limited only to glass insulators and does not cover those made of

polymers.

RESULTS

To verify the correct functioning of the

application, actual data were taken from Table 4. These data were entered into

the application following the order of the user interface in each of its four

sections of data to be entered and selected. Finally, a report was generated

with each case presented in Table 4.

Tests 1, 2 and 4 considered “anti-pollution” or

“anti-fog” profile insulators based on “heavy” pollution level and the

insulator characteristics shown in Table 4. The insulator model chosen for the

tests has very similar characteristics to the ones shown in the table, since

the same model is not found in the database. It is worth mentioning that the

insulator model with the same characteristics was applied in test 3 since it is

in the database.

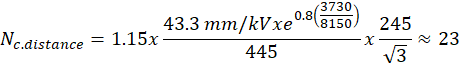

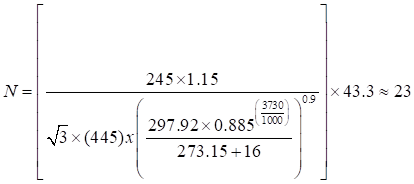

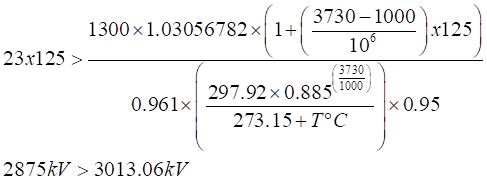

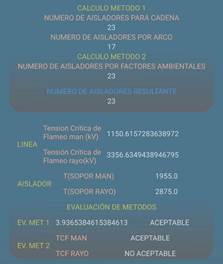

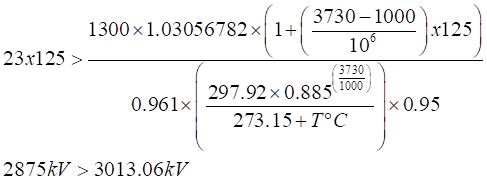

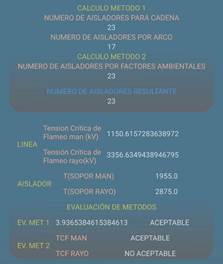

Case 3 calculation:

The manual calculation process will be done using

the data of case 3.

Method 1:

Method 2:

With both methods, the number of insulators is

23.

Evaluation of method 1:

Equation 14 is used considering the data of case

3 finding that:

CF = 3.53

This result is contrasted with Figure 1 and is

observed to be within limits.

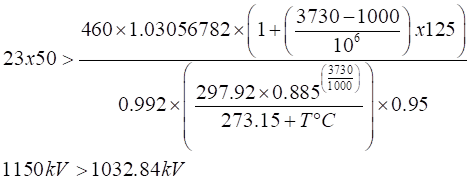

Evaluation of method 2:

It is evaluated with equations 21 and 24, so that:

Switch critical flashover voltage evaluation (equations 20 and 21)

As the withstand voltage of the string at the

switch critical flashover voltage (1150 kV) is higher

than that calculated in the phase, it will be considered

as an acceptable evaluation.

Lightning critical flashover voltage evaluation (equations 23 and 24)

As the withstand voltage of the string in lightning

critical flashover voltage (2875 kV) is lower than that calculated in the phase, it will be considered as an

unacceptable evaluation.

Note: This process is performed with the data

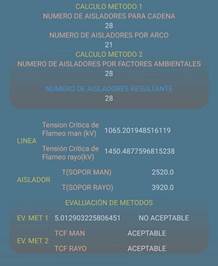

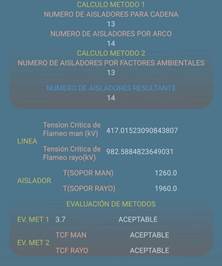

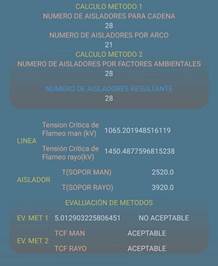

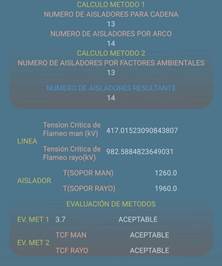

required in the equations and within the application. The results of all cases

are shown in Figures 8, 9, 10 and 11 through screenshots taken during the

tests.

Figure 8. Results

of Test 1.

Source: Prepared by

the authors (screenshot).

Figure 9. Results of Test 2.

Source: Prepared by

the author (screenshot).

Figure 10. Results of Test 3

Source: Prepared by

the authors (screenshot).

Figure 11. Results

of Test 4.

Source: Prepared by

the authors (screenshot).

Figure 12. Results of Test 5.

Source: Prepared by

the authors (screenshot).

Figure 13. Results of Test 6.

Source: Prepared by

the authors (screenshot).

The contrast of results is shown in Table 6,

where it is possible to appreciate both the results obtained by the application

according to the number of resulting insulators, and the result of the

evaluations of the methods described above. From this it can be seen that tests

1, 2, 3 and 4 have 100% certainty and tests 5 and 6 have 93.75% and 90%

respectively, which shows that hypothesis 1 is correct.

For hypothesis 2, the range of acceptability is

above 66%. It means that at least two of the three evaluations of the

calculation method have the term “Acceptable”, which validates the hypothesis.

Table 6. Contrast of

results according to calculation memories and those obtained from the application.

|

TESTS

|

1

|

2

|

3

|

4

|

5

|

6

|

|

Transmission Line 500 kV La Niña – Piura Nueva

|

Transmission Line 2 x 220 kV Piura Nueva – Piura Oeste

|

Sub-Station Friaspata

|

Design and Construction of Sub-transmission

line to 69 kV Songa

|

Transmission

Line 220 kV Reus – Tarragona

|

Transmission Line 220 kV Reque – Nueva Carhuaquero

|

|

Number of insulators (calculation memory)

|

28

|

14

|

23

|

5

|

15

|

18

|

|

Number of insulators (application)

|

28

|

14

|

23

|

5

|

16

|

20

|

|

Percentage of closeness to actual results

|

100%

|

100%

|

100%

|

100%

|

93.75%

|

90%

|

|

Creepage factor evaluation

|

Non acceptable

|

Acceptable

|

Acceptable

|

Acceptable

|

Acceptable

|

Acceptable

|

|

CFO switching Evaluation

|

Acceptable

|

Acceptable

|

Acceptable

|

Acceptable

|

Acceptable

|

Acceptable

|

|

CFO lightning Evaluation

|

Acceptable

|

Acceptable

|

Non acceptable

|

Acceptable

|

Acceptable

|

Acceptable

|

|

Acceptability percentage of results

|

66%

|

100%

|

66%

|

100%

|

100%

|

100%

|

Source: Prepared by

the authors.

DISCUSSION

The results of the application presented in

Table 6 exactly coincide with COES (2016a, 2016b), SIEMENS (2016) and Orellana

and Cevallos (2019), whose calculations are based on actual projects. However,

the results of the application disagree with tests 5 and 6. Likewise, in the

evaluations of the calculations, it is highlighted that tests 2, 4, 5 and 6

show results termed “Acceptable” in the three evaluations. However, test 1

failed in the evaluation of the creepage factor, which determines that the

profile of the anti-pollution insulator is not acceptable. Likewise, test 3

failed in the evaluation of the lightning critical flashover voltage, therefore

the lightning withstand is not adequate. In this regard, it should be

emphasized that the limitation of the application is not being able to enter

the data of a new insulator, since, for this reason, in tests 2 and 4,

insulators with very similar characteristics had to be used. This does not mean

that the calculated string does not work, but that changes in the insulator

model can and should be made to obtain a better response from the evaluation of

calculation methods.

CONCLUSIONS

The calculation optimization through the

prototype application shown in this study meets the proposed objective, which was

to optimize the dimensioning of glass insulator strings by means of a prototype

application. In addition, the two hypotheses proposed were demonstrated and

validated through the tests performed using real data from transmission line

projects, where the results obtained from the application were mostly totally

satisfactory. In addition, the practical use of the application makes it a very

interesting and didactic tool with a great potential for the user, who only

needs their cell phone to perform the dimensioning. In this way, the objective

of easy accessibility and correct dimensioning is achieved.

ACKNOWLEDGMENT

To God, for granting us the sense and wisdom to

overcome every obstacle that we encountered during the development of this study.

To our families and colleagues, for their

unwavering support when problems arose. Thank you for giving us your moral and financial

support throughout our professional journey. Without your support, we would not

have been able to complete this study.

To professor Millán Montalvo, for his constant

encouragement, guidance, and knowledge that were instrumental in the completion

of this research study.

REFERENCES

[1]

Comité de Operación Económica del Sistema Interconectado

Nacional. (2016a). Enlace 500 kV La Niña - Piura, Subestaciones, Líneas y

ampliaciones asociadas - PARTE I.

[2]

Comité de Operación Económica del Sistema Interconectado

Nacional. (2016b). Enlace 500 KV La Niña - Piura, Subestaciones, Líneas y

ampliaciones asociadas - PARTE II.

[3]

Comité de Operación Económica del Sistema Interconectado Nacional. (2018). Anteproyecto «Línea de

transmisión de 220 kV Reque - Nueva Carhuaquero y subestaciones asociadas».

Pepsa Tecsult. https://www.minem.gob.pe/minem/archivos/Enlace%20220%20kV%20Reque%20Nueva%20Carhuaquero.pdf

[4]

Cotto Macul, Z. Y. (2021). Análisis

del nivel de aislamiento utilizados en sistemas de distribución y

subtransmisión aéreas mediante el software ATP-DRAW. (Degree project).

Universidad Politécnica Salesiana, Guayaquil.

[5]

De la Fuente, M. (2016). Modificación

de línea aérea de alta tensión por cambio de conductor y de tensión. (Final degree project). Universidad de Valladolid,

Valladolid. https://uvadoc.uva.es/bitstream/handle/10324/17055/TFG-P-356.pdf?sequence=1&isAllowed=y

[6]

Díaz Sierra, H. R., & Narváez

Gómez, R. O. (2015). Evaluación para la

coordinación de aislamiento y distancias eléctricas en subestaciones de 220 Kv

y 500 Kv en altitudes entre 2.500 y 5.500 m.s.n.m. (Degree project). Universidad Pontificia Bolivariana,

Medellín. https://repository.upb.edu.co/handle/20.500.11912/2431

[7]

International

Electrotechnical Commission. (1993). Insulation co-ordination. Part 1: Definitions, principles and rules (IEC

60071-1:1993).

[8]

International

Electrotechnical Commission. (1996). Insulation co-ordination. Part 2:

Application guide (IEC

60071-2:1996).

[9]

International

Electrotechnical Commission. (2008a). Selection and Dimensioning of

High-Voltage Insulators Intended for use in Polluted

Conditions. Part 1: Definitions Information and General Principles (IEC/TS 60815-1:2008).

https://webstore.iec.ch/publication/3573

[10] International Electrotechnical Commission. (2008b). Selection and Dimensioning of High-Voltage Insulators

Intended for use in Polluted Conditions. Part 2: Ceramic and Glass Insulators

for A.C. Systems (IEC/TS 60815-2:2008). https://webstore.iec.ch/publication/3574

[11] LaForest, J. (1982). Transmission Line

Reference Book. 345 kV and Above/Second Edition. Palo Alto, CA, USA:

Electric Power Research Institute.

[12] López Salazar, J. P. (2018). Instalación Eléctrica De

MT, Centro De Transformación Y Red De BT En El Polígono Industrial De Valverde

Del Fresno (Caceres). https://contrataciondelestado.es/wps/wcm/connect/717ffde5-7146-43ee-badb-980b9c905502/DOC20181001110905Proyecto+final+Valverde+del+Fresno.pdf?MOD=AJPERES

[13] Mendoza Jasso, C., Rocha Lerma, P. F., &

Santiago Bautista, H. (2013). Diseño de la Coordinación

de Aislamiento para una Línea de Transmisión Compacta de 230KV. (Tesis de grado). Instituto Politécnico Nacional, México

D. F.

[14] Olives Piris, R. (2016). Línea de

transporte de energía eléctrica de 220 kV y 200 MVA. (Trabajo de fin de

grado). Universidad Politécnica de Cataluña.

[15] Orellana Riofrio, D. I., & Poma Quinche, J. C. (2014). Fabricación

a nivel de laboratorio del aislador eléctrico de cerámica tipo ANSI 53-2 y sus

respectivos bastidores para sujeción en mampostería. (Degree project).

Escuela Politécnica Nacional, Quito.

[16] Orellana Ochoa, W. W., & Cevallos Álvarez, L. G. (2019).

Diseño Construcción de la línea de Subtransmisión a 69KV Songa. (Degree

project). Universidad Politécnica Salesiana, Guayaquil.

[17] Portero Calderón, R. P. (2019). Coordinación óptima de

aislamiento en líneas de transmisión de alto voltaje considerando restricciones

de contaminación. (Degree project). Universidad Politécnica Salesiana Sede

Quito, Quito.

[18] Sediver. (2018). Sediver®

toughened glass insulators for HVAC applications. https://www.sediver.com/wp-content/uploads/C28-2018_Canada.pdf

[19] SIEMENS.

(2016). Memoria de cálculo selección de cadenas de aisladores (SA-REP,

PE-FRMO-GP015).

[20] VERESCENCE. (2019). Aisladores

de Vidrio. LaGranjaInsulators. https://studylib.net/doc/25849106/03-full-catalogue-lagranjainsulators-es-en-2019-low

![]() (1)

(1)![]() (2)

(2)![]() (3)

(3)![]() (4)

(4)![]() (5)

(5)![]() (6)

(6)![]() (7)

(7)![]() = Safety factor to avoid flashover in insulators

= Safety factor to avoid flashover in insulators ![]() and

and ![]() will be placed in expanded form, therefore two final equations are

displayed for the calculation of the number of insulators of method 1, which

will depend on the condition of the diameter of the insulator, therefore the

equations are as follows:

will be placed in expanded form, therefore two final equations are

displayed for the calculation of the number of insulators of method 1, which

will depend on the condition of the diameter of the insulator, therefore the

equations are as follows:![]() (8)

(8)![]() (9)

(9)![]() will be greater than 1 when the

altitude is greater than 1000 m.a.s.l., otherwise, the value of the unit will

be considered.

will be greater than 1 when the

altitude is greater than 1000 m.a.s.l., otherwise, the value of the unit will

be considered.![]() : Reference Unified Specific Creepage Distance (mm/kV)

: Reference Unified Specific Creepage Distance (mm/kV)![]() : 0.5 (normal), 0.8 (anti-fog)

or 1 (spherical or aerodynamic) according to IEC-60071-2 (1996)

: 0.5 (normal), 0.8 (anti-fog)

or 1 (spherical or aerodynamic) according to IEC-60071-2 (1996)![]() :

maximum operating voltage

:

maximum operating voltage![]() : creepage distance of the insulator (catalog)

: creepage distance of the insulator (catalog)![]() : average insulator diameter (nominal diameter if the insulator

does not have different diameters)

: average insulator diameter (nominal diameter if the insulator

does not have different diameters)![]() : height above sea level (m.a.s.l.)

: height above sea level (m.a.s.l.)![]() (10)

(10)![]() ” is catalog data, “

” is catalog data, “![]() ” is the critical phase-to-earth distance that relates to the

IEC-60815-2 creepage factor (IEC, 2008b). This distance will be given by table

A-1 of IEC-60071-2 (1996).

” is the critical phase-to-earth distance that relates to the

IEC-60815-2 creepage factor (IEC, 2008b). This distance will be given by table

A-1 of IEC-60071-2 (1996).![]() : insulator vertical spacing (mm)

: insulator vertical spacing (mm)![]() : critical phase-to-earth distance (mm)

: critical phase-to-earth distance (mm)![]() (11)

(11)![]() : total nominal creepage distance of the insulator

: total nominal creepage distance of the insulator![]() : arcing distance of the insulator (critical distance)

: arcing distance of the insulator (critical distance)![]() (12)

(12)![]() (13)

(13)![]() (14)

(14)![]() is the number of insulators resulting from method 1.

is the number of insulators resulting from method 1.

![]() (cm/hg) (15)

(cm/hg) (15)![]() (16)

(16)![]() )

)![]() (17)

(17)![]() )

)![]() )

)![]() depends on the relative humidity and temperature. For a frequency

of 60hz, a double-entry table (Table 3) was made using two curve graphs to

obtain the value of the

depends on the relative humidity and temperature. For a frequency

of 60hz, a double-entry table (Table 3) was made using two curve graphs to

obtain the value of the![]() , which makes it an important database in the development of the application.

, which makes it an important database in the development of the application.