Revista Industrial Data 27(1): 115-136 (2024)

DOI: https://doi.org/10.15381/idata.v27i1.25643

ISSN: 1560-9146 (Impreso) / ISSN: 1810-9993 (Electrónico)

Improvement in Preventing Occupational Health and Safety Risks: The Case of a Metalworking Company in a Mine

Evelyn Lisbeth Olazábal Ticona[1]

Production and Management

Submitted: 06/07/2023 Accepted: 06/10/2023 Published: 15/07/2024

DOI: https://doi.org/10.15381/idata.v27i1.25643.g20442

ABSTRACT

The mine currently under study is located in Peru and works with contractors to execute related activities. The employer must promote a culture of occupational risk prevention during activities. In this research article, the agile methodology was used to identify its processes and the performance status in each guideline of the Occupational Health and Safety Management System (OHSMS). This was the basis for the design and implementation of tools to manage the measurement and control of the OHSMS. The results demonstrated that the measurement and timely control of the OHSMS increased occupational risk prevention compliance from 62% to 89%, which made it possible to safely complete the project.

Keywords: occupational risk prevention; processes; guidelines; OHSMS; management tools.

INTRODUCTION

In Peruvian mining, several activities are directly related to exploitation and other related activities, which contribute greatly to Peru’s GDP. Contractors are strategic allies of mines for the execution of their associated activities, which are increasing every year. During the execution of projects such as installing safety guards in a mine’s primary crushing bays, the employer must ensure the occupational health and safety (OHS) protection of workers during their work activities. Therefore, it is important to have management tools that comply with each guideline of an Occupational Safety and Health Management System (OSHMS). The development of this project is of great importance for the company and requires planning and continuous follow-up.

This research introduces a new methodology for gathering information based on the concepts and standards of the sector in which the company operates. The methodology can be applied to various contractors involved in related activities at mines in Peru. The first contribution of this methodology is to help companies comply with legally obligatory regulations and avoid severe legal sanctions, such as fines and other penalties. The second contribution is to provide companies with an analytical approach that helps them recognize their OHS status within their company and improve their management tools to ensure that their employees are protected at work in terms of safety and health. The third contribution is to provide a more direct way to evaluate performance, which can be used as an indicator to immediately detect non-compliance. Finally, the methodology describes how compliance issues were controlled in each OHSMS guideline, which is one of the main challenges faced by any company.

A similar sequence was used in the research concerning the OHSMS conducted by Aguilar and Gonzáles (2016), Jiménez (2016), Mosqueira (2016), and Vásquez (2016).

Figure 1. Sequence for establishing an OHSMS.

Source: Prepared by the author

Figure 1 illustrates the six-step sequence followed by these authors for establishing an OHSMS:

· An analysis and diagnosis of the company must be carried out to eliminate or mitigate hazards and avoid economic losses.

· Direct and field observation of working conditions accompanied by questionnaire-type surveys are used as diagnostic tools.

· Results are compared with the country’s Health and Safety norms and regulations.

· Risk assessment using the Hazard Identification, Risk Assessment and Control Measures (HIRARC) matrix and the analysis of previous incidents help identify critical risks.

· Finally, the authors concluded that implementing an OHSMS improved the safety performance of the work and the health of the employees of the company under study.

Mariño et al. (2016) proposed a documentary structure for the occupational safety and health management system (OHSMS) that identifies and evaluates risks, establishes controls, and reduces latent risks in an organization.

This research is significant to the field. Previous research studies have led to the setting of the general objective of designing and implementing an OHSMS to enhance the performance of preventing occupational risk in the project where safety guards are installed for the primary crushing bays in a mine.

The study has two specific objectives:

1) Evaluate the OHS status of the project where safety guards are installed for a mine’s primary crushing bays.

2) Design and implement the OHSMS to enhance occupational risk prevention in the project where safety guards are installed for a mine’s primary crushing

The general hypothesis is that designing and implementing an OHSMS enhances occupational risk prevention in a project where safety guards are installed for a mine’s primary crushing bays.

The study has two specific hypotheses:

a) Evaluating the OHS status in a project where safety guards are installed for a mine’s primary crushing bays makes it possible to design an OHSMS for the project.

b) Implementing an OHSMS improves occupational risk prevention in a project where safety guards are installed for a mine’s primary crushing bays.

The findings of this study provide a fresh perspective by implementing established techniques, but with a system that enables swift identification of hazards, risk assessment, and control measures. This system is suitable for organizations in the metalworking sector, particularly those involved in the Peruvian mining sector. It aims to complement and improve the processes of the organization. The agile systematized process structure allows for a complete analysis of activities.

Although there have been no reported workplace accidents in this metalworking company before this study, the nature of the project activities and personnel behavior needs a management system that prioritizes safe work practices and a secure work environment to prevent labor risks.

The main limitation of this research was the short time available to respond to occupational risks during the installation of safety guards. However, this limitation actually served as a catalyst for the development of agile management tools.

Process-Based Management

Process-based management is a methodology that systematizes an organization by interrelating its process. It involves organizing inputs, resources, needs, and outputs through a sequence of procedures that meet customer requirements and add value. This process is outlined in a process characterization sheet, which helps structure the company’s processes under study.

Determining the Cause of Accidents

One of the main objectives of occupational risk prevention is to avoid workplace accidents. To achieve this, it is necessary to identify their causes.

Cortés (2007) mentions a model that identifies the various factors that are interrelated before a workplace accident occurs: Surry’s model. This model shows human behavior towards an accident, from a human factor approach and a technical factor approach.

Causal Chain Analysis Method

The causal chain analysis method, according to Berruezo (2002), is a methodology that examines an event in reverse order. This approach helps investigators determine:

a. the damage caused to people, processes, and/or equipment;

b. the sequence of events;

c. any sub-standard conditions;

d. personal or labor factors;

e. and failure during preventive measures.

Epidemiological Model

Arévalo (2016) explains that Reason (1997) proposed the Swiss Cheese Model due to the limitations of linear models. This model shows the complexity of how active failures interact with latent conditions.

A latent condition refers to any accident that could happen, while active failures or unsafe acts are observable directly.

Therefore, it is necessary to have a system in place to manage barriers that protect against latent conditions. However, if there is an error or lack of compliance with human or organizational factors, the latent condition can be left without a protective barrier, and an accident can occur.

OHSMS Planning

Different theories are presented in order to plan the OHSMS. One of them is the Plan-Do-Check-Act (PDCA) cycle.

Betancur and Vanegas (2017) applied the PDCA method to process improvement. This seven-step methodology contains the solution to problems that occur in the four moments of the cycle.

Traditionally, to solve a problem, actions were established to save the moment without first analyzing the cause(s) of the problem. The PDCA tool is successful when applied systematically in each of its steps:

a. problem selection;

b. understanding the problem;

c. performing root cause analysis, planning each solution;

d. gathering data from the plan and evaluating results;

e. comparing each result obtained with the expected one to identify deviations;

f. discarding the cause whose performance is unsatisfactory, then setting a standard; and

g. monitoring standards with the inclusion of the opportunity for improvement and moving on to a new cycle.

Occupational Health and Safety Management System (OHSMS)

According to the International Labor Organization (Organización Internacional del Trabajo, 2001), it is the responsibility of every employer to ensure occupational safety and health (OSH) by complying with national laws and regulations. Employers must demonstrate leadership and a strong commitment to all OSH activities and provide everything necessary for the OSHMS, including establishing policy, organizing, planning, implementing, evaluating, and taking action to improve.

Man-Machine-Environment Interaction

According to García (2002), an emission refers to the operational information presented by a machine, which is transmitted by a source such as recording boards. This information is perceived by humans and then interpreted as correct or incorrect based on their acquired knowledge. Based on their decision, they transmit the action to the machine through controls. The machine processes the action and emits new information on the recording board, and the cycle continues until the working day is over or the interaction stops. Therefore, humans need to be trained to interpret information correctly to perform their work correctly.

METHODOLOGY

Questionnaire

Rodríguez (2005) maintains that by applying observation as a technique, researchers can use questionnaires to focus on key points based on certain parameters. For this study, the questionnaire was developed based on applicable standards.

Interview

Rojas (1991) explains that using interviews is crucial for exploratory studies as it allows researchers to gather more extensive information based on the problem under study. This technique is particularly helpful when there is not enough information available for investigating elements.

Similarly, Rodríguez (2005) mentions that in order to establish a direct relationship between the researcher and the object of study, interviews need to be conducted with people related to the subject of study, and, in this way, collect verbal testimony.

In this study, upper and middle management verified compliance with each guideline in the OHSMS using a checklist.

Observation

Implementing a tool that manages reports by acts or substandard conditions is beneficial in identifying the hazards in situ during the completion of the project under study.

As mentioned by Rodríguez (2005), observation is a way of recording responses identified by our senses. The author classifies observation into two types: direct and indirect.

Direct observation is when the researcher collects data through their observation using two modalities. Modality 1 occurs when the researcher is part of the population under investigation, while modality 2 occurs when the researcher observes directly but is not a participant in the population under investigation. On the other hand, indirect observation is when information is collected by people other than the researcher but is corroborated by the researcher.

Data Analysis and Interpretation

To analyze and interpret information, it must be categorized using tabulation (Rodríguez, 2005)

According to Montero (2007), qualitative and quantitative data can be represented through three types of diagrams: pie charts, bar diagrams, and Pareto charts. A pie chart represents the relative or absolute frequencies of qualitative information in sectors of a circle. A bar diagram represents information collected in rectangular bar graphs, while a Pareto chart is a combination of bar charts and a polygon consisting of cumulative lines of frequencies.

To evaluate whether implementing the OHSMS improves occupational risk prevention performance in the project under study, compliance with each OHSMS guideline was evaluated. Three types of compliance were established based on the score obtained: yes, regular, and no. The OHSMS was then classified into four levels: acceptable, regular, low, and not acceptable.

RESULTS

Analysis, Interpretation and Discussion of Results

Situational Diagnosis

A situational diagnosis was conducted for each OHSMS guideline to evaluate the OHS status of the project for the installation of safety guards in a mine’s primary crushing bays, as shown in Figure 2.

Figure 2. OHSMS guidelines.

Source: Prepared by the author (Ley N.º 29783, 2011; D.S. N.º 005-2012-TR, 2012; D.S. N.º 024-2016-EM, 2016; R. M. N.º 050-2013-TR, 2013).

The company manager and the project supervisor were interviewed using the OHSMS guidelines checklist to collect the information before design and implementation. The results are shown in Figure 3.

Figure 3. Percentage of compliance by guideline - Initial status.

Source: Prepared by the author.

The results obtained have identified the management tools available to the organization and the areas that need improvement.

OHMSM Baseline

The performance status of each guideline in the OHSMS baseline was rated as “Regular” with a score of 333 points, according to the classification outlined in Table 1.

Table 1. OHMS Baseline Score - Initial Status.

|

Final Diagnostic Score |

OHSMS Classification |

|

0-119 |

Not Acceptable |

|

120-238 |

Low |

|

237-357 |

Regular |

|

358-476 |

Acceptable |

Source: R.M. N.º 050-2013-TR (2013).

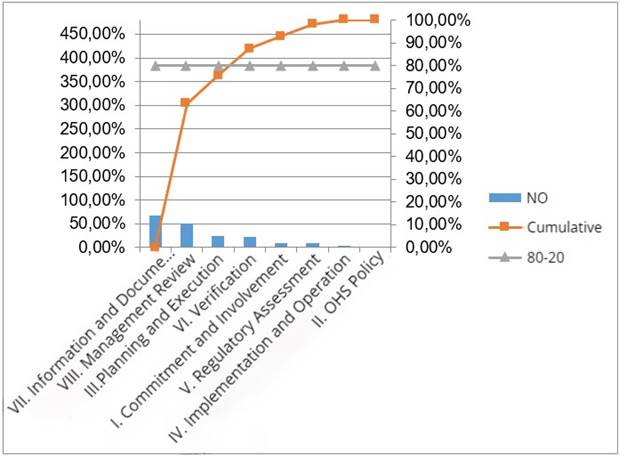

A Pareto diagram (Figure 4) was elaborated before implementing the OHSMS tools to better identify non-compliance with important and unimportant guidelines.

Figure 4. Pareto diagram of non-compliance with guidelines.

Source: Prepared by the author.

From Figure 4, it was found that 80% of the predicted internal non-compliances come from 20% of the causes attributable to the guidelines vi) Verification, i) Commitment and Involvement, v) Regulatory Assessment, iv) Implementation and Operation, and ii) Occupational Health and Safety Policy.

Process Mapping

To identify hazards and evaluate their risks, a Process Mapping (Table 2) was developed to collect information through the Characterization Sheet of the project’s processes and field interviews

Table 2. Process Mapping.

|

Activity |

Task |

Position |

|

|

Installation of Safety Guards in a Mine’s Primary Crushing Bays |

Transfer of personnel, equipment, and tools |

Mobilization and demobilization |

* Driver |

|

Lifting of loads using cranes |

* Crane operator |

||

|

Manual transfer of equipment and tools |

* Journeyman |

||

|

Topographic survey |

Layout and stakeout |

* Surveyor |

|

|

Excavation |

Manual excavation of trenches |

* Construction worker |

|

|

Material supply |

Wooden formwork fitting out |

* Construction worker * Journeyman |

|

|

Steel formwork erection |

* Construction worker |

||

|

Concrete pouring |

Formwork |

* Construction worker * Journeyman |

|

|

Concrete mixing and pouring |

* Construction worker * Journeyman |

||

|

Formwork stripping |

* Construction worker * Journeyman |

||

|

Concrete profiling |

* Construction worker |

||

|

Hauling of material |

Lifting of structures using a crane |

* Crane operator |

|

|

Supply of input |

Welding of structure |

* Welder |

|

|

Structure surface preparation |

* Painter |

||

|

Painting of structures |

* Painter |

||

|

Scaffolding erection |

Scaffolding erection and dismantling |

* Scaffolder |

|

|

Building of structures |

Lifting and assembly of “P” structures and panels |

* Crane operator * Rigger |

|

|

Welding of structures |

* Welder |

||

|

Mechanical cleaning of structures |

* Welder |

||

|

Painting of structures |

* Painter |

Source: Prepared by the author.

HIRARC Matrix

The Hazard Identification, Risk Assessment and Control Measures (HIRARC) matrix was then elaborated with the critical elements identified in the records of field observations.

OHSMS Documents

A master list of documents that would make up the OHSMS was developed to determine the level of effectiveness of the OHSMS. This list made it possible to assess the OHSMS performance before and after its implementation. The safety performance results were compared with the performance level of each implemented OHSMS guideline.

The implementation of specific documents in the guidelines of vi) Verification, i) Commitment and Involvement, v) Regulatory Assessment, iv) Implementation and Operation, and ii) Occupational Health and Safety Policy reduced the percentage of non-compliance. The result is shown in Figure 5, which demonstrates the percentage of compliance by guideline after implementation.

Figure 5. Compliance percentage per guideline - Final.

Source: Prepared by the author.

A comparison between Figure 3 and Figure 5 shows the percentage of initial and final compliance with the OHSMS guidelines (Table 3), indicating that the non-compliance percentage (“no”) decreased to 0%. Therefore, the compliance percentage (“yes” and “regular”) increased.

Table 3. Initial and Final Percentage of Compliance with OHSMS Guidelines.

|

Guidelines / Compliance |

Yes |

Regular |

No |

|||

|

Initial |

Final |

Initial |

Final |

Initial |

Final |

|

|

1st Commitment and Involvement |

60% |

80% |

30% |

20% |

10% |

0% |

|

2nd OHS Policy |

50% |

92% |

50% |

8% |

0% |

0% |

|

3rd Planning and Execution |

65% |

100% |

12% |

0% |

24% |

0% |

|

4th Implementation and Operation |

84% |

100% |

12% |

0% |

4% |

0% |

|

5th Regulatory Assessment |

86% |

86% |

5% |

14% |

9% |

0% |

|

6th Verification |

70% |

83% |

9% |

17% |

22% |

0% |

|

7th Information and Document Control |

33% |

89% |

0% |

11% |

67% |

0% |

|

8th Management Review |

50% |

83% |

0% |

17% |

50% |

0% |

|

Average percentage |

62% |

89% |

15% |

11% |

23% |

0% |

Source: Prepared by the author.

Table 3 shows that all eight OHSMS guidelines are 89% fully complied with and the remaining 11% are being implemented to reach 100%.

Hypothesis Testing

The research question is whether the design and implementation of an OHSMS can improve the prevention of occupational hazards for a project involving the installation of protection guards in a mine’s primary crushing bays. Based on this, the general hypotheses were stated as follows:

· Ho = Designing and implementing an OHSMS does not improve the prevention of occupational risks for the project where safety guards are installed for a mine’s primary crushing bays.

· Ha = Designing and implementing an OHSMS has little impact on preventing occupational risks for the project where safety guards are installed for a mine’s primary crushing bays.

To determine if the data follows a normal distribution, a Shapiro-Wilk normality test was performed with a significance level of 5% (α = 0.050). The results show a value of 0.436 for ωc and a value of 0.842 for ωt. As ωc is less than ωt, it is concluded that the data do not follow a normal distribution.

A correlation analysis was conducted using Spearman’s test. The result revealed a high correlation coefficient of 0.821 between the variables. This led to the performance of a Student’s t-test, which resulted in a value of t = 4.070. Since this value falls outside the acceptance region of the hypothesis test (−2.306 to 2.306), Ho is rejected and Ha is accepted. This confirms that increased levels of SGSSO implementation lead to improved prevention of occupational risks during the installation of safety guards in a mine’s primary crushing bays.

DISCUSSION

After analyzing the results obtained from interviews, direct field observation, and questionnaires, it was possible to improve the HIRARC Matrix in each guideline for the OHSMS per the rules and regulations.

First Guideline:

· Top Management initiated an Incentive and Recognition Program to evidence their commitment and involvement in complying with OHS standards. This program involved both Top Management and workers.

· The Baseline HIRARC matrix was updated for all activities related to the project.

Second Guideline:

· The OHS policy was improved to include all activities carried out by the company and to ensure a commitment to complying with standards and continuous improvement.

· A safety budget was drafted and approved by the upper management.

Third Guideline:

· It is important to initially evaluate each guideline as a starting point or participatory base diagnosis of the state of workplace health and safety, compared to established country laws and sector standards. An inspection program was implemented.

Fourth Guideline:

· All critical activities were included in the training program.

· The Baseline HIRARC matrix and the map where each risk is located were updated and disseminated.

· Procedures were established for all emergencies through a plan describing the formation of emergency brigades and all actions to be taken to respond to any emergency.

· A procedure was implemented to channel communications.

Fifth Guideline:

· Guidelines were established for the procedure for identifying and assessing legal requirements.

· Measures were included in the Baseline HIRARC matrix to avoid hazardous work for pregnant or breastfeeding workers as per law.

Sixth Guideline:

· The record of substandard acts and conditions format (RACS in Spanish) was implemented for better identification of safety issues to be reinforced in both workers and working conditions.

· The progress of the Annual OHS Program is recorded.

· The Baseline HIRARC matrix and procedures were updated according to current activities.

Seventh Guideline:

· A communications procedure and suggestion box, as well as the employee suggestion form, were implemented to improve the control of information and documents.

· Health and safety recommendations were included in all staff employment contracts.

· Improvements were also made to the procurement procedure.

· A list of documents was implemented to control current and obsolete versions.

Eighth Guideline:

· Management’s participation contributed greatly to obtaining information during the checklist review in which each OHSMS guideline was verified.

· The OSHMS review meeting was held, with recent information from the project that had started a few months ago.

OSHMS Baseline - After Implementation

· The performance status of each OSHMS Baseline guideline (OSHMS checklist) after implementation of the improved OSHMS scored 435 and was classified as “Acceptable”, as shown in Table 4.

Table 4. OHMS Baseline Score - Final Status.

|

Final Diagnostic Score |

OHSMS Classification |

|

0-119 |

Not Acceptable |

|

120-238 |

Low |

|

237-357 |

Regular |

|

358-476 |

Acceptable |

Source: R.M. N.º 050-2013-TR (2013).

Based on the results obtained from the research, it was initially observed that the OHS status of the company, which was evaluated with a score of 333 points, fell under the “regular” level. This evaluation was done by identifying compliance with each OHSMS guideline and comparing the score with the parameters of different levels such as “acceptable”, “regular”, “low”, and “not acceptable”. This evaluation allowed the design of the project’s OHSMS by applying the necessary tools for adequate management in each guideline.

After implementing the OHSMS, a new evaluation was carried out, which resulted in 435 points, an “Acceptable” level, and was higher than the initial evaluation, 333 points. Therefore, it is evident that implementing the OHSMS has improved occupational risk prevention during the installation of safety guards in a mine’s primary crushing bays.

These results can be applied to other organizations by carrying out a situational diagnosis of the OHSMS guidelines and classifying them into three types of compliance: Yes, Regular, and No. This would help identify the management tools available to an organization and which must be implemented. After implementation, the organization would evaluate the diagnosis of the guidelines to verify the improvement of the organization in risk prevention. This process should be repeated as part of continuous improvement in the organization.

CONCLUSIONS

· In a constantly changing work environment where various activities related to mining require contractors to work safely, any management system must be designed and implemented in accordance with all business activities, while also complying with the country’s laws and sector standards.

· Identifying the OHS status of the project under study allowed for determination of the level of compliance with the OHSMS guidelines.

· The OSHMS aspects studied for the installation of safety guards in a mine’s primary crushing bays to improve occupational risk prevention were the management tools identified in the list of OSHMS documents.

· The Baseline HIRARC matrix was updated to include controls implemented with the field task observation, planned work observation, and reports on acts or sub-standard conditions by improving the organization’s processes through process mapping. This made it possible to prevent occupational risks for collaborators, as the number of acts and sub-standard conditions decreased at the end of the project.

ACKNOWLEDGMENT

I would like to express my gratitude to God, my family, and all those people who gave me their unconditional support.

REFERENCES

[1] Aguilar, R., & Gonzáles, D. (2016). Diseño de un sistema de gestión de seguridad y salud ocupacional basado en las normas OHSAS 18001:2007 y Ley 29783, para disminuir el número de accidentes en la empresa Metal Mecánica SIBAN SRL-Cajamarca. (Degree thesis). Universidad Nacional de Trujillo, Trujillo.

[2] Arévalo Sarrete, C. (2016). Metodologías y técnicas analíticas para la investigación de accidentes de trabajo. Madrid, Spain: Fundación Agustín de Betancourt de la ETSICCP.

[4] Berruezo Varela, D. C. (2002). Causalidad de los accidentes de trabajo. https://factorhuma.org/attachments_secure/article/6696/PREVENCION.pdf

[7] Decreto Supremo N.º 024-2016-EM. Aprueban Reglamento de Seguridad y Salud Ocupacional en Minería. El Peruano Normas Legales: 595392-595447. (2016, July 28).

[8] García Acosta, G. (2002). La ergonomía desde la visión sistémica. Bogotá, Colombia: Unibiblos.

[9] Jiménez Cervantes, N. (2016). Implantación de un sistema de gestión de seguridad y salud ocupacional en Comercial Molinera San Luis, Lambayeque. (Master’s thesis). Universidad Nacional de Trujillo, Trujillo.

[11] Mariño, C., Castro, Y., & Cruz, A. (2016). Diseño del Sistema de Gestión en Seguridad y Salud en el Trabajo Bajo la Normatividad Vigente para la Empresa Industria Metalmecánica “Inmecom Ltda.” Ubicada en el Barrio Ricaurte - Bogotá. (Degree thesis). Universidad Distrital Francisco José de Caldas, Bogotá. http://hdl.handle.net/11349/4316

[12] Montero Lorenzo, J. M. (2007). Estadística descriptiva. Madrid, Spain: Thomson Ediciones Paraninfo.

[13] Mosqueira Arce, H. (2016). Diseño de sistema de gestión de seguridad y salud en el trabajo para industria de plásticos - PROCOMSAC - en Chiclayo. (Master’s thesis). Universidad Nacional de Trujillo, Trujillo.

[14] Organización Internacional del Trabajo. (2001). Directrices relativas a los sistemas de gestión de la seguridad y la salud en el trabajo. Geneva, Switzerland: Oficina Internacional del Trabajo.

[15] Reason, J. (1997). Managing the Risks of Organizational Accidents. Brookfield, Vermont, U.S.: Ashgate Publishing.

[16] Resolución Ministerial N.º 050-2013-TR. Aprueban formatos referenciales que contemplan la información mínima que deben contener los registros obligatorios del Sistema de Gestión de Seguridad y Salud en el Trabajo. El Peruano Normas Legales: 490909-490909 (2013, March 15).

[17] Rodríguez Moguel, E. A. (2005). Metodología de la Investigación. Tabasco, Mexico: División Académica de Ingeniería y Arquitectura UJAT.

[19] Vásquez, M. (2016). Implantación de un Sistema de Gestión de Seguridad y Salud Ocupacional en el Proyecto Especial Olmos-Tinajones, Lambayeque. (Master’s thesis). Universidad Nacional de Trujillo, Trujillo.