Revista Industrial Data 27(2): 33-49 (2024)

DOI: https://doi.org/10.15381/idata.v27i2.26905

ISSN: 1560-9146 (Impreso) / ISSN: 1810-9993 (Electrónico)

Utilizing Kipa as a Technology Innovation for Reactive Cotton Dyeing Processes Aligned with The SDGs for Handmade Garment Production

Design and Technology

Submitted: 26/10/2022 Accepted: 13/09/2023 Published: 18/12/2024

DOI: https://doi.org/10.15381/idata.v27i2.26905.g20449

Adriana Edith Cachay Anardo[1]

Renato Bellin Cier[2]

Pablo José Lupis Davila[3]

ABSTRACT

Reactive dye is one of the most widely used for textile fiber dyeing due to the colorfastness properties that fibers exhibit after the dyeing process, which results from a covalent reaction between the dye and the fibers. However, to achieve adequate colorfastness levels, hydrolyzed dye must be removed through extensive rinsing. Consequently, there is a high consumption of resources such as water, time, and energy. Given the importance of preserving natural resources, particularly water—an essential element in the dyeing process—it is crucial to identify periods when water consumption can be minimized. The most significant water waste occurs during the soaping and rinsing stages after dyeing; approximately 70% of the water used in the reactive dyeing process is consumed during these stages. This research paper aims to optimize cotton dyeing through a process known as “Kipa” to reduce resource consumption, particularly water, and minimize the use of toxic substances, such as sodium chloride and auxiliary chemicals. Additionally, temporal and thermal parameters, including pH and affinity, and the costs of the products will be examined to optimize the dyeing process.

Keywords: textile industry, cotton dyeing, reactive dyeing, sustainable reagent dyeing, sustainability.

INTRODUCTION

The world is currently experiencing significant environmental damage due to global warming. Among the most polluting industries, the textile sector is ranked second, surpassed only by the oil industry.

An ecological study has shown that the reactive dyeing process of 100% cotton fibers produces polluted effluent that is harmful to the environment, people, and businesses. Reactive dyeing is not only a waste of resources but also depletes our precious drinking water, as a substantial portion of toxic water is discharged untreated, adversely affecting aquatic life and polluting our water resources. Furthermore, this process is outdated, time-consuming, and costly.

This research paper aims to contribute to the field by evidencing and highlighting the potential of the textile sector in our country. It advocates for improvements in the production chain by developing a new dyeing system that can reactivate the industry based on innovation while monitoring and mitigating environmental impact.

The Kipa process addresses the environmental complications associated with the reactive dyeing of 100% cotton fibers, making dyeing more efficient and sustainable. By reducing water consumption by 60% and eliminating sodium chloride from the process, Kipa helps preserve freshwater resources due to the compatibility of cotton and dye, and sodium chloride is no longer necessary.

Moreover, Kipa lowers energy consumption, shortens dyeing time, and reduces the use of toxic dye products, resulting in clean effluent. Sustainability and economy are not mutually exclusive; dyehouses can increase their production capacity by 300%.

The research further examines the impact of the Kipa dyeing process on technical performance and compliance with international standards established by the American Association of Textile Chemists and Colorists (AATCC). This study involves technical validation of the Kipa process in batches of at least 400 kg, leveraging available technological infrastructure and software. The findings aim to demonstrate how the metrics and technical-commercial value of the Kipa formula enhance the effective promotion of an environmentally friendly proposal.

Today, reactive dye is the most used for the colorfastness properties it provides to textiles after the dyeing process, as it forms a covalent bond with the fibers. However, to achieve adequate colorfastness levels, hydrolyzed dye must be removed through extensive rinsing. Consequently, there is a high consumption of resources such as water, time, and energy.

This research paper aims to optimize cotton dyeing through a process known as “Kipa” to reduce resource consumption, particularly water, and minimize the use of toxic substances, such as sodium chloride and auxiliary chemicals. This endeavor has led to the development of a new and innovative product: Kipa cotton.

Pima cotton, renowned globally for its fineness, softness, and extra-long fibers, offers a competitive edge in demanding and knowledgeable markets. However, Pima cotton is not the only natural fiber that stands out in the textile sector. The development of Kipa cotton aligns with the stringent parameters of the Sustainable Development Goals (SDGs), particularly Goal 6: Clean water and sanitation, which aims to ensure sustainable access to water and sanitation for all.

Background

The International Trade Center (2011) conducted research aimed at fostering growth among Peruvian websites specializing in alpaca garments to increase their competitiveness. Romosa stands out as a leading company in the production of special yarns, including heather, flamé, injected, mouliné, and others, made from 100% cotton or blends of cotton with various fibers (alpaca, linen, bamboo, modal, viscose, tencel, polyester, etc.). The company’s commitment to high quality and innovation has positioned it as the top-of-mind choice for its customers, who use its fibers in products exported mainly to the United States and Europe. These customers work with Peruvian exporters, using Romosa’s products to meet the demands of high-profile fashion brands such as Patagonia, Hugo Boss, Michael Kors, Ralph Lauren, and Vineyard Vines, among others, with products that meet the demands of international markets.

Ocampo (2019), in her study Optimización del proceso de teñido reactivo de tejidos de algodón sin afectar la apariencia y la solidez al lavado, en el área de tintorería de una empresa textil localizada en Lima-Perú demonstrates the feasibility of process optimization in a dyeing plant to increase production while maintaining quality standards—without compromising quality or appearance—and reducing costs. This applied, explanatory research explores and describes the reactive dyeing process to establish a correlation between various variables. The conclusion drawn is that optimizing the soaping cycle can lead to a 13% increase in production.

Quinto (2022), in her research study Decoloración por electro-oxidación de efluentes textiles del proceso de teñido de algodón con colorantes reactivos, notes that industrial waste has a detrimental impact on water bodies due to inadequate wastewater treatment. The textile industry consumes large quantities of water due to the various chemical agents used, resulting in wastewater laden with pollutants from the dyeing process. To address this issue, Quinto applies an electro-oxidation methodology using titanium mesh for the simulated and actual decolorization of dyeing wastewater, allowing for its potential reuse.

Sucasaca (2022), in his research study Efectos del colorante natural inflorescencia de colli (Buddleja coriacea) en la solidez de color del teñido de fibras de alpaca, Puno 2021, aimed to extract the yellow pigment from colli inflorescences for dyeing alpaca fibers to assess its impact on the colorfastness of dyed alpaca fibers. To that end, 16 dye samples were tested in a laboratory. Various factors, including mordant concentration, temperature, and dyeing time were modified to obtain different outcomes.

Pallo (2022), in her research, emphasizes the importance of recognizing artisanal techniques such as loom weaving from the Salasaca community for making accessories. The accessories design market is shifting as more customers prioritize durable, eco-friendly items. Fashion designers have created a global trend by collaborating with skilled artisans, blending traditional techniques like weaving, embroidery, dyeing, and culturally significant motifs, adding value to products. Marketing efforts are integral to the project, helping to generate financial returns locally, with structural and functional planning for pieces made from regional materials such as animal and plant fibers.

Similarly, Mamani (2020), in her research Efectos del teñido natural con cúrcuma (Curcuma longa) en la solidez del color del hilado de alpaca para la artesanía textil, Puno 2020, aims to determine how natural dyeing with turmeric affect the colorfastness of alpaca fiber. Using a hypothetical-inductive methodology, Mamani focused on alpaca yarn produced in Conduriri over the last five years, with a non-probabilistic predetermined sample of 38 yarn specimens. Results showed that substrate/plant ratio, dyeing time, and dyeing temperature affect wet rub fastness and dry rub fastness. For colorfastness to wet rubbing, a rating of 4.17 was achieved, the optimal conditions were found to be a plant/substrate ratio of 9%, a dyeing time of 30 minutes, and a temperature of 98 ºC. For colorfastness to dry rubbing, a rating of 4.5 was obtained, the optimal conditions were a 9% substrate/plant ratio, a dyeing time of 30 minutes, and a temperature of 85°C; however, the treatments exhibited low overall colorfastness.

One limitation of the research is the economic factor; while the Peruvian textile industry is a key employment driver, industries must invest to meet international demand. Despite the potential and advantages of the textile sector due to the high volume and quality of cotton fiber produced, which boosts our global standing, challenges remain. These include a lack of training for the workforce in weaving techniques and quality standards suitable for Nordic markets, along with limited direct involvement in the garment negotiation process.

Origin

Kipa cotton is a chemically modified version of regular cotton that constantly change its electrical charge. The name “cotton” originates from the Arabic word gunt and belongs to the Gossypium genus. Depending on the variety and region, its green stems can grow between 0.8 and 1.5 meters tall. When flowering, the stem color shifts from green to red. Its heart-shaped leaves have five lobes, its flowers can be red or white with spots, and its fruit is a capsule containing an average of 15 to 20 seeds (Romosa S.A.C., 2021b).

Cotton is known for being the finest fiber, and its cultivation dates back to ancient times. Initially, the term cotton semantically referred to “fine fabric”. It played a vital role in the development of the Indian textile industry.

Advantages and Disadvantages of Cotton

Advantages: easy to keep warm, moisture-absorbing, soft fit, breathable, resistant to alkalis and heat, clean and hygienic.

Disadvantages: prone to shrinking, pilling, and wrinkling, not very smooth in appearance, and needs frequent ironing.

Types of Cotton

A technical report by Romosa S.A.C. (2021c) compares the current reactive dyeing process for cotton with that of Kipa cotton. It defines the technical characteristics and minimum international standards established by the AATCC. The report also categorizes the different types of dyeing based on the following classifications:

· Indian cotton: It is a short-fiber cotton and the lowest quality cotton.

· American cotton: It is a medium-fiber cotton, also known as “Upland cotton”.

· Egyptian cotton: It is an extra-long fiber cotton that produces high-quality fabrics.

· Pima cotton: It is renowned as the best cotton in the world, celebrated for its quality, durability, and exceptional softness. Originally from Arizona, this cotton variety was later introduced to Peru, where it thrived due to the favorable climate. Pima cotton is a long-fiber cotton grown mainly in Peru, the United States, Australia, and some Latin American countries. Its softness, durability, and resistance set it apart as the finest cotton available.

· Premium raw cotton: It is a 100% natural cotton yarn, free from dyes and chemical treatments. One of its main features is its softness, making it very pleasant to the touch and an ideal choice for manufacturing all types of garments.

· Tangüis cotton: It is an important traditional Peruvian export product. It is primarily produced in Ica and has been cultivated in Lima since the 20th century. This cotton variety has revolutionized the textile industry in Peru.

Sustainability

According to a report by Romosa S.A.C. (2018b), Kipa is an innovative dyeing process that uses less dyestuff, lower temperature, less steam, energy, chemicals, and water. It does not require textile salt, sodium carbonate, or caustic soda. The reactive dyeing cycles are shorter due to dye exhaustion and achieve better colorfastness.

The Kipa process was entirely designed and executed by Romosa’s internal team. As a result, from initial planning to completion, they developed a comprehensive document of the procedure, which will serve as a technical reference for future research teams within the company.

The project was named “Kipa”. After three years of research and innovative development, the team created a prototype (100% self-funded) for a new, sustainable fabric dyeing process. Following its development, laboratory tests were conducted, obtaining satisfactory results regarding water quality indicators after the dyeing process (BOD, COD, pH, hydrolyzed dye, suspended solids, among others). Tests were conducted on a sample dyeing machine, with batches of 25 kg, resulting in over 100 batches processed to date.

According to the United Nations (2018), the textile industry is the second largest polluter globally surpassed only by the oil industry, producing up to 20% of polluted effluents and 10% of global carbon emissions—more than all international flights and cargo ships combined.

According to Soto (2020), the textile industry is responsible for 20% of industrial effluent pollution generated by textile processing and produces over 15 000 chemicals throughout its production, beginning with fiber manufacturing.

Sustainability is becoming an essential factor for thousands of customers. Three out of five people between the ages of 20 and 40 already demand sustainable products. Concern for the environment, which started as a trend, has now become a necessity for life preservation. In response, new products with sustainable processes have been proposed in the textile market. All stakeholders have shown significant interest and requested continuous monitoring to ensure that sustainability indicators are met. This proposal is crucial, as it would provide real-time reporting on compliance with the sustainability parameters verified in lab reports. This information would ultimately add value for end customers.

Characteristics of Reactive Dyes

According to Romosa S.A.C. (2021a), the primary properties of reactive dyes are as follows:

Reactivity: This refers to the dye’s fixation capability, indicating the amount of dye dissolved and allowing for the assessment of pigment elimination during the dyeing process. Based on reactivity, dyes are classified into three types:

1. Normal reactive dyes: Yield up to 50%, reacting at temperatures between 75° to 90°C.

2. Pigments with high reactivity: Yield up to 75%.

3. Very high reactivity reactive dyes: Have a reaction rate between 92% and 94% at temperatures from 45° to 60° C and are used for continuous and semi-continuous dyeing.

Substantivity: Reactive dyes have low substantivity, requiring a high salt concentration to reach exhaustion.

Diffusion: High-reactivity dyes have a high diffusion capability compared to regular dyes.

Affinity: It refers to the reaction of the fibrous pigment, stemming from the difference in chemical capacity between the dyebath and the fiber in a standard state. In terms of chemical potential, affinity reflects the attraction between the dye and the fiber, represented in units of work. Conceptually, it measures the energy or force required to separate the dye from the fiber. The correspondence of reactive dyes depends on chromophore groups and the reactive system.

During the dyeing process, dissolved pigment molecules tend to occupy more space, leading to an increase in energy. As dye molecules adhere to the fiber, they reach a lower disorder state and thus require an external force to facilitate this transition, referred to as “affinity”. Affinity is crucial in the fixation process, as higher results in better fixation only if it reaches or exceeds the affinity threshold. Greater dye affinity for cellulose correlates with a higher percentage of dye absorbed by the fiber, thereby fulfilling the conditions of the dyeing process and achieving a greater degree of fixation. Because some reactant pigments have a low affinity for cellulose, their fixation or adhesion capability remains unchanged.

The duration of the dyeing process is limited in the sense that if the exhaustion and fixing process is too rapid, uneven dyeing may occur. Such inconsistencies must be avoided; otherwise, the fixed dye may not be even, requiring stripping or over-dyeing to correct the color (Villegas, 2012).

Reactive Dye Properties

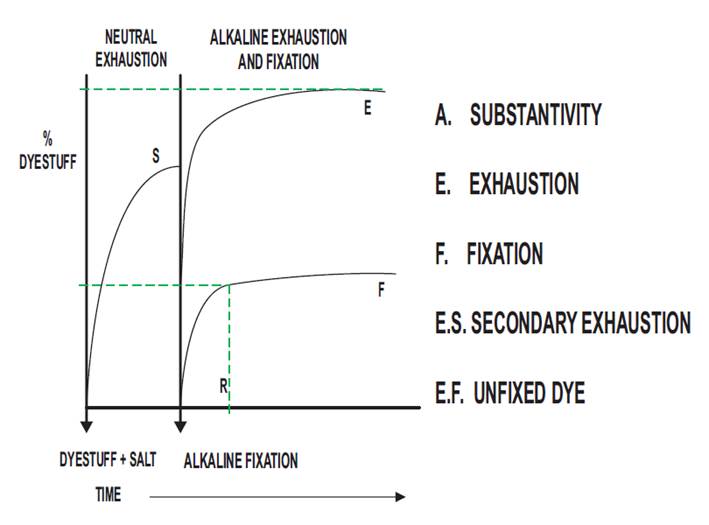

Romosa S.A.C. (2018a) determines the properties of reactive dyes by exhaustion, solubility, substantivity, and fixation, as outlined in Figure 1.

Figure 1. Reactive dye properties.

Source: Romosa S.A.C. (2018a).

Properties that develop in the reactive dyeing process of cotton may vary depending on the specific process conducted. High exhaustion values indicate that a minimal amount of dye remains in the process effluent, while low exhaustion values correspond to high dye levels remaining in the effluent. Fixation percentage represents the degree of covalent bonding to the substrate, based on the original dye used in the dyeing process.

METHODOLOGY

Research Hypotheses

H1: Implementing technical validation of the Kipa formula ensures its use for minimum volumes of 400 kg, verifying compliance with AATCC standards.

H2: Utilizing available technology and software optimizes the dyeing process and enables effective monitoring of environmental indicators.

The variables involved in the research study on the use of Kipa as a technology innovation for the reactive dyeing process of cotton aligned with the SDGs are listed in Table 1.

Table 1. Variables.

|

|

Independent Variable |

Dependent Variable |

|

H1 |

Kipa formula |

Minimum volume and compliance level with AATCC standards |

|

H2 |

Technological equipment and software |

Optimization of the dyeing process |

Source: Prepared by the authors.

To address the research problem, a quantitative approach with an experimental design was adopted to establish a cause-effect relationship between variables: reactive cotton dyeing and technical regulations and international AATCC standards.

The applied research employs a true experimental design, analyzing multiple variables and utilizing pre-and post-tests to assess the progress of the experimental groups. The design includes a control and an experimental group, both measured posttest. The control group consisted of was composed of reactive cotton, while the experimental group used Kipa cotton, structured as follows:

Control group (CG): - O1

Experimental group (GE): X O2

Where:

X: Application of treatment (Kipa)

O1, O2: Post-test indicator measurements

The unit of analysis consisted of 400 kg of cotton. The population included all kilograms of cotton produced by the company. Tests were conducted following the AATCC methodology. The research sample, necessary for conducting tests and adjustments, has a volumetric weight of 400 kg, reflecting the average weight of cotton purchased in the market.

RESULTS

The results for the control group (reactive cotton) and the experimental group (Kipa cotton) are shown in Table 2.

Table 2. Volume and Level of Compliance with AATCC Standards in Minimum Quantities of 400 kg of Cotton.

|

Indicators |

Reactive Cotton |

Kipa Cotton |

|

Sodium chloride consumption |

160 kg |

0 kg |

|

Sodium carbonate consumption |

16 kg |

0 kg |

|

Caustic soda consumption |

6.4 kg |

0 kg |

Source: Prepared by the authors.

As shown in Table 2, 30 batches of 400 kg were tested. For each batch, reactive cotton dyeing used 160 kg of sodium chloride, 16 kg of sodium carbonate, and 6.4 kg of caustic soda. In contrast, Kipa cotton dyeing does not require these chemicals, instead using Synozol Ultra Navy DS-R dye. Since the indicators remained constant across all samples, inferential testing was not applied. The indicators show no data variability, as they remain constant in all samples; thus, an inferential test is not applicable.

The results for the control and experimental groups related to hypothesis 2 are shown in Table 3.

Table 3. Optimization of the Dyeing Process.

|

Indicators |

Reactive Cotton |

Kipa Cotton |

|

ISO 105-E01 - Colorfastness to water |

hydrolysis 30% |

Does not undergo hydrolysis |

|

ISO 12945-2 - Fabric resistance to pilling |

3 (moderate pilling) |

4 (slight pilling) |

|

AATCC TM 61 - Colorfastness to accelerated laundering |

Lower exhaustion (4 on the quality gray scale) |

Higher exhaustion (5 on the quality gray scale) |

|

Impact on health |

Polluted wastewater |

Clean wastewater |

|

Water consumption |

72 L/kg |

24 L/kg |

|

Energy consumption |

180 minutes ≈ 649.98 kW |

108 minutes ≈ 389.97 kW |

Source: Prepared by the authors.

As can be seen in the “ISO 105- E-01 - Colorfastness to water” indicator, reactive cotton shows a hydrolysis reaction of 30% in each sampled batch, whereas Kipa cotton shows no hydrolysis reaction due to the absence of chemicals in its dyeing process, unlike reactive cotton.

Regarding the “ISO 12945-2 - Fabric resistance to pilling” indicator, on the AATCC/ISO gray scale, reactive cotton scored a three (3), defined as moderate pilling, while Kipa cotton scored a four (4), defined as slight pilling.

Regarding the “AATCC TM 61 - Colorfastness to accelerated laundering” indicator, reactive cotton scored a four (4) on the gray scale, reflecting 80% colorfastness, while Kipa cotton scored the maximum value of five (5), indicating superior colorfastness and an advantage in product quality.

Regarding health impacts, reactive cotton dyeing generates contaminated wastewater, while Kipa cotton dyeing produces clean wastewater.

In terms of water consumption, reactive cotton dyeing requires 72 L/kg, compared to 24 L/kg for Kipa cotton dyeing, which consumes 66% less water than reactive cotton dyeing.

In terms of energy consumption, reactive cotton dyeing takes 180 minutes and 649.98 kW, whereas Kipa cotton dyeing takes 108 minutes and 389.97 kW. In other words, there is a substantial 40% reduction in processing time for Kipa cotton dying compared to reactive dyeing.

DISCUSSION

The research highlights the suitability of Kipa cotton as a raw material on an industrial scale, optimizing the environmental indicators. Beyond tests and adjustments, tools were used to establish a baseline for the reactive dyeing process, allowing for comparison with the Kipa dyeing process, and validating indicators by positive results.

A regulatory protocol for constant monitoring was established, and metrics were digitalized to facilitate analysis and communicate improvements in sustainability indicators to customers, who required detailed process information. OEKO-TEX certification is necessary for validation tests conducted with volumes of 400 kg.

With validated parameters and appropriate environmental oversight, this process has benefited customers, who provided feedback on final product quality and noted the benefits gained throughout the process, considering that the textile industry is the second most polluting industry and is a significant consumer of water.

The project demonstrates a high level of sustainability during the dyeing process, unique on a global scale, reducing water, energy, and chemical consumption. Customers in this industry increasingly demand sustainable products and transparency to assess the impact metrics related to environmental mitigation.

Regarding the evaluation and comparison of results between reactive cotton dyeing and Kipa cotton dyeing, the proposal had a significant impact, reducing environmental pollution by up to 90% during the dyeing process. This reduction is particularly notable, considering the fashion industry is the second most polluting industry globally, according to the United Nations.

The process required 40% less manufacturing time, 66.7% less water, and 20% less energy—metrics unmet in the textile industry, providing a competitive advantage in sustainable markets. The installed capacity of the dyehouse was maximized, reaching up to 150 tons per month for this line, driving projected sales to over S/70 million by 2025 and cumulative project sales to more than S/130 million that year.

Significant savings (+S/1 million) were achieved by reducing water, energy, dyes, and temperature, and eliminating the use of textile salt, sodium carbonate, and caustic soda. This allowed for offering the product at a competitive price in the market.

The product portfolio was expanded, allowing clients to offer high-value sustainable products to niche markets that can be certified. This contributed to the economic recovery of the sector and its international positioning.

In comparison to previous studies, this research optimized environmental mitigation indicators, while the research by the International Trade Center (2011) had a different objective, focusing on the growth of the alpaca garment trade.

This study shares similarities with the work of Ocampo (2019), as both studies focus on cotton dyeing processes; however, they differ in production increases for cotton dyeing. Ocampo’s study observed a 13% increase, whereas the present study achieved 40%.

While this research minimizes wastewater pollution, it differs from Quinto’s study (2022), which uses reactive dyes with negative impacts on water bodies.

Another distinction is found in the dyeing technique; this research used the Synozol Ultra Navy DS-R dye, while Sucasaca (2022) used natural colli inflorescences dye for the dyeing of alpaca fibers.

This research study resembles that of Pallo (2022) in its objective, which aimed to identify artisanal techniques such as loom weaving to protect the environment using environmental indicators.

Lastly, it is related to the study by Mamani (2020), which focuses on colorfastness in the dyeing process, with an emphasis on low contamination by using natural products in the dyeing process.

CONCLUSIONS AND RECOMMENDATIONS

Kipa reactive cotton dyeing is a sustainable process that prioritizes the conservation of natural resources, creating a competitive advantage in economic and ecological terms within the textile sector.

The optimization of this process results in significant cost savings, turning it into a profitable project.

Kipa reactive cotton dyeing is more durable, stable, and environmentally friendly over time for several reasons:

· It does not require sodium chloride and alkali, such as carbonate and caustic soda.

· It uses 32% less dyestuff to achieve the same hue.

· It has higher dye exhaustion rates, leading to improved colorfastness.

· The reactive dyeing cycle is shorter due to dye exhaustion.

· It requires lower temperatures, less steam, and less energy.

· It reduces and potentially eliminates rinsing, using 67% less water to remove unfixed colorant.

· It produces less waste from dyes and chemicals, resulting in cleaner effluents, which is crucial as the textile industry is the second most polluting in the world.

Moreover, this research is expected to double the company's employment by 2025.

REFERENCES

[1] American Association of Textile Chemists and Colorists. (2023). AATCC Manual of International Test Methods and Procedures.

[2] Mamani Puma, E. J. (2020). Efectos del teñido natural con cúrcuma (cúrcuma longa) en la solidez del color del hilado de alpaca para la artesanía textil, Puno 2020. (Degree thesis). Universidad Nacional de Juliaca, Juliaca. http://repositorio.unaj.edu.pe/handle/UNAJ/191

[3] Naciones Unidas. (2018, July 24). Objetivos del desarrollo sostenible. Noticas ONU: mirada global historias humanas. https://news.un.org/es/story/2018/07/1438312

[4] Ocampo Dávila, S. S. (2019). Optimización del proceso de teñido reactivo de tejidos de algodón sin afectar la apariencia y la solidez al lavado, en el área de tintorería de una empresa textil localizada en Lima-Perú. (Degree thesis). Universidad Nacional Mayor de San Marcos, Lima. https://cybertesis.unmsm.edu.pe/handle/20.500.12672/10758

[5] Pallo Núñez, D. C. (2022). Diseño de accesorios con tejidos artesanales de la comunidad Salasaca elaborados en el caserío Manzapamba Grande. (Integrated Project required for earning a degree). Repositorio Universidad Técnica de Ambato, Ambato. http://repositorio.uta.edu.ec/handle/123456789/36083

[6] Quinto Sánchez, M. (2022). Decoloración por electro-oxidación de efluentes textiles del proceso de teñido de algodón con colorantes reactivos. (Degree thesis). Universidad Nacional de Ingeniería, Lima. https://renati.sunedu.gob.pe/handle/sunedu/3321991

[7] Romosa S.A.C. (2018a). Memoria Técnica resumida del proyecto KIPA.

[8] Romosa S.A.C. (2018b). Proceso innovador del teñido que se emplea menor cantidad de colorantes, temperatura, vapor, energía eléctrica, químicos, agua, no necesita sal textil, carbonato de sodio, soda caustica, con ciclos más cortos, teñidos reactivos por agotamiento de colorante.

[9] Romosa S.A.C. (2021a). Definiciones.

[10] Romosa S.A.C. (2021b). Informe de prospección comercial. Lima: Industrial Romosa S.A.C.

[11] Romosa S.A.C. (2021c). Memoria técnica de comparación del proceso de teñido actual de algodón reactivo versus el proceso de teñido de algodón reactivo kipa, definiendo las características técnicas y estándares mínimos internacionales requeridos por la ATCC. Lima: Compañía industrial ROMOSA S.A.C.

[12] International Trade Center. (2011). Empowering Peruvian Woman Business Enterprises in Alpaca to enter the US Market. https://www.intracen.org/news-and-events/news/working-with-partners-to-empower-women-and-power-trade

[13] Soto Méndez, M. (2020, April 22). Industria de la moda es responsable del 10% de las emisiones mundiales. Ojo al clima. https://ojoalclima.com/articles/industria-de-la-moda-es-responsable-del-10-de-las-emisiones-mundiales

[14] Sucasaca, A. (2022). Efectos del colorante natural inflorescencia de colli (Buddleja coriacea) en la solidez de color del teñido de fibras de alpaca, Puno 2021. http://repositorio.unaj.edu.pe:8080/xmlui/bitstream/handle/UNAJ/213/TESIS_%202022_ALEXANDER%20SUCASACA%20QUISPE_ITC.pdf?sequence=1&isAllowed=y

[15] Villegas Pita, S. E. (2012). Optimización de la fase de jabonado en la tintura de algodón 100% con colorantes reactivos mediante la evaluación y selección de una fórmula técnicamente desarrollada. (Degree thesis). Universidad Técnica del Norte, Ibarra. http://repositorio.utn.edu.ec/bitstream/123456789/1957/1/TesisFormatoPdf.pdf

Authors’ contribution

Adriana Edith Cachay Anardo (first author): Investigation, formal analysis, writing (review & editing).

Renato Bellin Cier (co-author): Investigation, formal analysis, and writing (review & editing).

Pablo José Lupis Davila (co-author): Investigation, formal analysis, and writing (review & editing).