Revista Industrial Data 27(2): 123-152 (2024)

DOI: https://doi.org/10.15381/idata.v27i2.26975

ISSN: 1560-9146 (Impreso) / ISSN: 1810-9993 (Electrónico)

Management Model based on Total Productive Maintenance (TPM) and Six Sigma to increase Overall Equipment Effectiveness (OEE) in a Textile and Apparel Company in Lima, Peru

Production and Management

Submitted: 20/12/2023 Accepted: 28/02/2024 Published: 31/12/2024

DOI https://doi.org/10.15381/idata.v27i2.26975.g20454

Jorge Enrique, Ortiz Porras [1]

Andrei Mikhailo, Bancovich Erquinigo[2]

Harold Smith, Quintana Saavedra[3]

Paola Lisbeth, Crispin Chamorro [4]

Lisseth Margarita, Huayanay Palma[5]

ABSTRACT

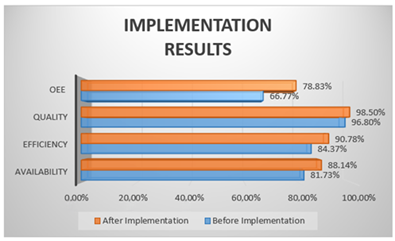

This article addresses the challenge of low overall equipment effectiveness (OEE) within the textile industry. It identifies the need to enhance equipment availability, quality, and performance to tackle sectoral challenges. The main objective of this research study aimed to develop and implement a management model based on total productive maintenance (TPM) and Six Sigma, using a textile company as a case study. A sample of 28 machines from the Weaving Department was taken and various tools were applied, including internal analysis, process flow diagram (PFD), failure mode and effects analysis (FMEA), Pareto analysis, cause-and-effect matrix, 5S, TPM, I-MR charts, and control plans. As a result, a remarkable increase of 9.09% in OEE was achieved, demonstrating specific improvements of 5.18% in equipment availability, 4.23% in performance, and 1.6% in quality.

Keywords: textile industry, Six Sigma, total productive maintenance, overall equipment efficiency.

INTRODUCTION

The textile industry pioneered the transformation brought about by the Industrial Revolution, significantly contributing to the development of many world economies and exerting considerable political influence over an extended period (Scheffer, 2012). Notably, the textile industry is characterized by being highly globalized within the industrial landscape (Lee et al., 2011). As such, it is a crucial sector for both industrialized and less-developed economies, serving as a key driver of wealth and employment generation. For instance, in Europe, it employs more than two million people (Slović et al., 2016), while in countries such as Bangladesh, the textile industry is the most economically significant and rapidly growing sector (Rahman et al., 2022).

In the Peruvian context, the textile industry holds particular relevance, as it contributes to culture and enriches the country’s identity (Fuentes et al., 2019). It is often viewed as a developed sector equipped with modern, high-tech machinery, which enhances the efficient use of human resources, increases productivity, improves working methods, and reduces production costs. This ultimately makes high-quality products available at lower prices (Salazar, 2020). According to Arroyo and Timaná (2022), the textile industry, particularly in Lima and the well-known textile hub of Gamarra, has played a pivotal role in Peru’s economy over the years, with notable technological advances throughout its history. However, the industry faces significant challenges, most notably regarding lead times, which are hindered by productivity issues in production (Slović et al., 2016). These challenges include limited financial resources, insufficient personnel and time, poor resource utilization, little or no experience, and limited trust in implementing new systems (Tangen, 2005).

Accordingly, the main objective of this research is to develop a model that integrates lean and Six Sigma methodologies, using the 5s and total productive maintenance (TPM) as key tools to increase the overall equipment effectiveness (OEE) within textile companies. A specific company will be used as a case study, primarily engaged in fabric production and the manufacturing of knitted garments, mostly polo shirts and jackets. With over 30 years of experience, it has achieved remarkable development and sustained growth in production volumes. However, its current performance is affected by various forms of waste, which have significantly reduced overall equipment effectiveness (OEE).

This research paper aims to contribute new knowledge to the scientific community by developing a model that integrates the best tools of the Lean Six Sigma framework, specifically tailored to the textile industries. Through theoretical and practical validation of this model, we aim to ensure its applicability to other companies within the sector. This model will serve as a guide to enhance the overall equipment effectiveness and pave the way for future research seeking to implement it in similar contexts.

Six Sigma

Six Sigma is a statistical analysis methodology that enables organizations to assess their current operational conditions and improve process performance to reduce variation and maintain quality results. Its primary goals are to minimize defects, increase profits, improve product quality, and enhance customer satisfaction (Mittal et al., 2023). This methodology uses a systematic implementation tool known as DMAIC, which involves defining the problem, measuring, analyzing, improving, and controlling processes (Kumar et al., 2018).

DMAIC

DMAIC, which stands for define, measure, analyze, improve, and control, is an implementation methodology based on data analysis used to optimize procedures. It employs a quality improvement framework tailored to the specific needs of an organization or project (Hannafin et al., 2023). In the DMAIC implementation phases, the “define” phase involves identifying improvement projects. The “measure” phase involves collecting data, performing statistical analyses, and establishing success indicators for the process in question. During the “analyze” phase, the gathered data are processed to determine the root causes of any process malfunctions. During the “improve” phase, effective solutions are implemented to address the identified problem. Finally, the “control” phase involves developing a control plan to ensure the improvements achieve the desired outcomes and are sustained over time (Garza et al., 2016).

5S

5S is a lean management tool designed to eliminate non-value-added processes in manufacturing industries, ensuring the standardization and organization of methods and processes (Andrés-López et al., 2015). Implementing this tool contributes to improving production efficiency and positively impacts workplace safety. A well-organized environment encourages employees to work more effectively (Senthil et al., 2022).

Total Productive Maintenance (TPM)

Total Productive Maintenance (TPM) is a comprehensive strategy involving employees’ active participation in continuous operation and maintenance activities (Au-Yong et al., 2022). This approach focuses on enhancing equipment effectiveness through preventive maintenance to eliminate disruptions such as breakdowns, accidents, and defects within the production system while reducing associated costs (Mushtopa et al., 2023).

Overall Equipment Effectiveness (OEE)

Overall equipment effectiveness (OEE) is a crucial metric for assessing sustainability improvement in a company’s processes compared to their initial state (Haddad et al., 2021). In addition to assessing the performance of machines and systems, OEE also provides valuable insights into the performance of personnel responsible for system maintenance (Sibarani et al., 2021).

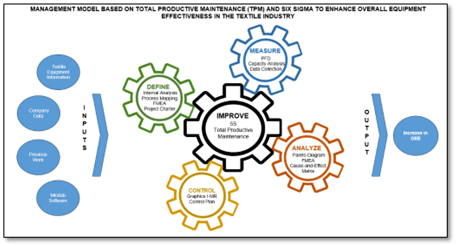

TPM and Six Sigma Model in the Textile Industry

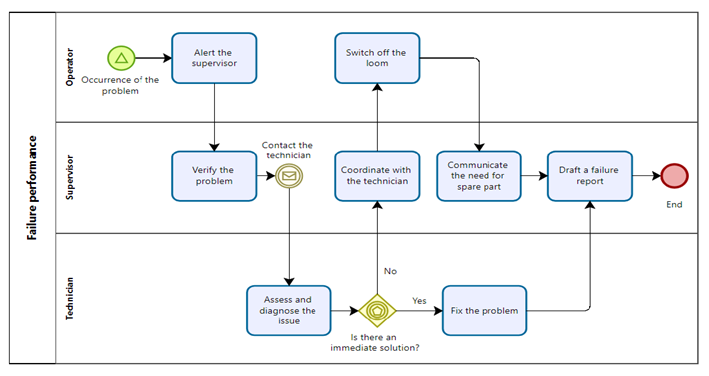

The model designed in this research study integrates the TPM tool with Six Sigma to enhance overall equipment effectiveness in a textile company. The model is illustrated in Figure 1.

Figure 1. Management model based on TPM and Six Sigma Model to enhance OEE in the textile industry.

Source: Prepared by the authors

METHODOLOGY

The research was conducted through a case study approach. This article demonstrates how implementing the developed model increases the overall equipment effectiveness in a textile company. The case study methodology was chosen due to its versatility in design and its flexibility in using both quantitative and qualitative analyses tailored to the needs and context of the company (Sánchez et al., 2020). Furthermore, this approach facilitates data collection through direct observation in established operating environments, allowing for a comparative analysis of the collected data (Sunder et al., 2019).

The research population was comprised of 30 pieces of equipment from the company’s Weaving Department. Using probabilistic sampling with a confidence level of 95% and a margin of error of 5%, the sample was determined to include 28 equipment pieces. The primary data collection techniques were direct observation and documentary review, employing instruments such as data recording forms tailored for each variable and a documentary analysis guide designed to assess the current context of the company.

Data was collected over three months, spanning the first and second quarters of 2023. This time frame allowed for comparing the state of operations before and after implementing the TPM and Six Sigma model. In the initial phase, data were collected, a comprehensive mapping of all company processes was conducted, and an evaluation of process capability and sigma levels was performed to understand its operations thoroughly.

RESULTS

Define Phase

The company under study operates in the textile and apparel sector and has more than 30 years of experience, successfully positioning itself in the market. Its main economic activity is the production of garments for export, with vertical integration as its main competitive advantage.

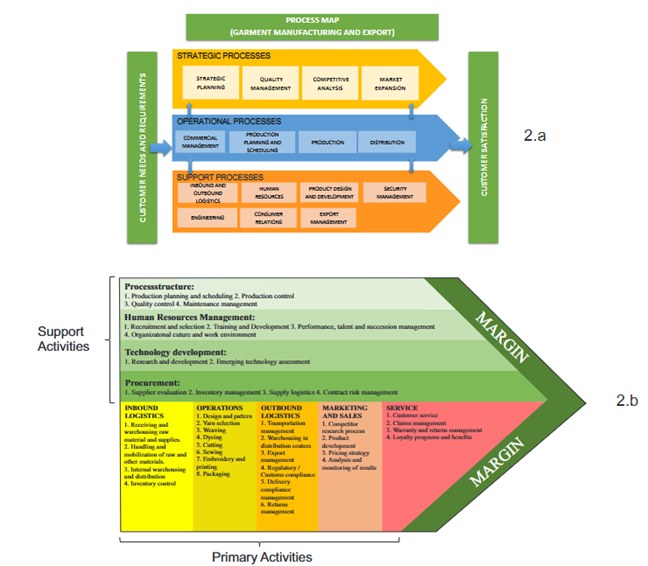

A macro-process mapping was created to understand how the interconnected parts of the company operate and how various functions and activities are related (Figure 2.a). Additionally, an internal analysis of the company was completed by identifying the value chain. This helped to understand how value is created, pinpoint areas for improvement, and illustrate how the processes within the production macro-process can be optimized, which is the focus of this study (Figure 2.b).

Figure 2. Internal analysis of the company.

Source: Prepared by the authors.

Following the internal analysis, a failure mode and effect analysis (FMEA) was conducted to determine which production process should be the focus of the study. The results are summarized in Table 1.

Table 1. FMEA of Production Processes.

|

PROCESS |

T-Shirt Manufacturing |

||||||

|

Process |

Subprocess Description |

Failure Mode |

Effect |

S |

O |

D |

RPN |

|

Design and Pattern |

The T-shirt design is developed either on paper or digitally, along with a pattern guide. |

Faulty pattern due to lack of maintenance |

Delay in the process |

3 |

2 |

2 |

12 |

|

Inadequate use of design tools |

Delay in the process |

2 |

4 |

4 |

32 |

||

|

Weaving |

The fabric is produced through the weaving process, where threads are interwoven to form the material. |

Irregular fabric due to lack of maintenance |

Unscheduled downtime/Generation of defects |

7 |

6 |

4 |

168 |

|

Wear and tear of critical parts |

Unscheduled downtime/Equipment failure |

7 |

5 |

8 |

280 |

||

|

Misalignment of needles or machine parts |

Generation of defects/Generation of waste |

7 |

8 |

6 |

336 |

||

|

Dyeing |

Change of fabric color according to specific requirements |

Poor dyeing results due to malfunction of the fixation equipment |

Generation of defects |

8 |

6 |

2 |

96 |

|

Lack of operator training in calibrating parameters on the fixation equipment |

Generation of defects/Generation of waste |

6 |

5 |

2 |

60 |

||

|

Cutting |

Using the pattern as a guide, the fabric is cut into the shapes needed for each part of the T-shirt. |

Cutting blade wear |

Generation of defects |

6 |

7 |

4 |

168 |

|

Irregular cutting due to lack of maintenance |

Unscheduled downtime/Equipment failure |

7 |

6 |

4 |

168 |

||

|

Sewing |

The cut pieces of fabric are sewn together to assemble the T-shirt. |

Wear and tear of sewing tools |

Generation of defects |

8 |

6 |

2 |

96 |

|

Printing or Embroidery |

If necessary, printing or embroidery can be applied. |

Poor machine calibration |

Generation of defects/Generation of waste |

7 |

4 |

6 |

168 |

|

Poor quality supplies |

Generation of defects |

6 |

5 |

4 |

120 |

||

Source: Prepared by the authors.

As shown in Table 1, the failure modes associated with the weaving process resulted in a higher risk priority number (RPN), leading to the decision to focus on this department. After completing the preliminary phase, the project was officially initiated with an incorporation act that defined, among other things, the problems, objectives, and scope of the project.

Measure Phase

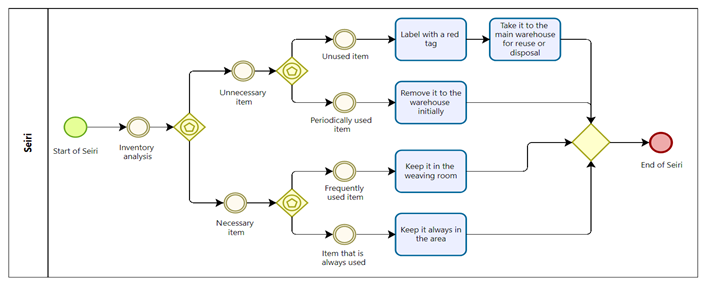

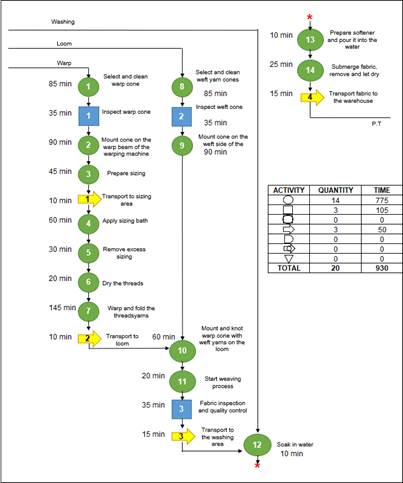

This phase began with the creation of a process flow diagram (PFD) to detail and visualize the weaving process in the textile company, aiming to understand and optimize this complex manufacturing process. Given the intricate nature of weaving—from yarn selection to quality control of the finished product—a clear and systematic representation of the operations involved was necessary. The PFD allowed each phase to be broken down into individual steps, allowing for the identification of potential inefficiencies, bottlenecks, and opportunities for improvement throughout the process, as illustrated in Figure 3.

.

.

Figure 3. Process flow diagram of the weaving process.

Source: Prepared by the authors.

Subsequently, data was collected on the current process capability, performance, quality, and availability of the 28 pieces of equipment in the area over a three-month period. The mean values are displayed in Tables 2 and 3.

Table 2. Current Capacity of the Weaving Process.

|

|

Short-Term Capacity |

Long-Term Capacity |

Sigma Level |

|

Week 01 |

0.27 |

0.28 |

0.17 |

|

Week 02 |

0.26 |

0.27 |

0.1 |

|

Week 03 |

0.25 |

0.27 |

0.11 |

|

Week 04 |

0.26 |

0.28 |

0.16 |

|

Mean |

0.26 |

0.275 |

0.135 |

Source: Prepared by the authors.

Table 3. Weaving Department Equipment: Availability, Performance, and Quality.

|

Equipment |

Availability |

Performance |

Quality |

Equipment |

Availability |

Performance |

Quality |

|

1 |

85.83% |

86.20% |

96.01% |

15 |

83.33% |

84.27% |

96.17% |

|

2 |

87.50% |

88.26% |

96.37% |

16 |

82.50% |

83.82% |

96.07% |

|

3 |

75.00% |

83.73% |

96.18% |

17 |

77.08% |

83.72% |

96.63% |

|

4 |

68.75% |

73.57% |

95.98% |

18 |

80.00% |

83.37% |

96.00% |

|

5 |

90.00% |

89.83% |

96.42% |

19 |

74.17% |

83.07% |

96.33% |

|

6 |

88.33% |

88.14% |

96.02% |

20 |

85.42% |

88.06% |

96.12% |

|

7 |

75.00% |

85.05% |

96.54% |

21 |

85.00% |

87.40% |

96.36% |

|

8 |

82.92% |

84.14% |

96.27% |

22 |

83.33% |

86.80% |

95.68% |

|

9 |

83.33% |

83.77% |

96.03% |

23 |

87.08% |

88.73% |

95.83% |

|

10 |

84.58% |

84.27% |

96.05% |

24 |

88.75% |

88.48% |

96.36% |

|

11 |

62.50% |

70.99% |

94.88% |

25 |

87.08% |

88.77% |

95.98% |

|

12 |

85.00% |

84.22% |

96.00% |

26 |

79.17% |

84.07% |

96.32% |

|

13 |

74.17% |

82.98% |

95.99% |

27 |

82.92% |

86.04% |

95.95% |

|

14 |

74.58% |

83.55% |

96.22% |

28 |

81.25% |

85.10% |

95.80% |

Source: Prepared by the authors.

Finally, the overall equipment effectiveness was calculated by multiplying availability, performance, and quality. The results are found in Table 4.

Table 4. Overall Effectiveness of the Weaving Process Equipment.

|

Equipment |

OEE |

Equipment |

OEE |

Equipment |

OEE |

Equipment |

OEE |

|

1 |

71.03% |

8 |

67.17% |

15 |

67.53% |

22 |

69.21% |

|

2 |

74.42% |

9 |

67.04% |

16 |

66.43% |

23 |

74.05% |

|

3 |

60.40% |

10 |

68.46% |

17 |

62.36% |

24 |

75.67% |

|

4 |

48.54% |

11 |

42.10% |

18 |

64.03% |

25 |

74.19% |

|

5 |

77.95% |

12 |

68.72% |

19 |

59.35% |

26 |

64.10% |

|

6 |

74.76% |

13 |

59.08% |

20 |

72.30% |

27 |

68.45% |

|

7 |

61.58% |

14 |

59.96% |

21 |

71.59% |

28 |

66.24% |

Source: Prepared by the authors.

Analyze Phase

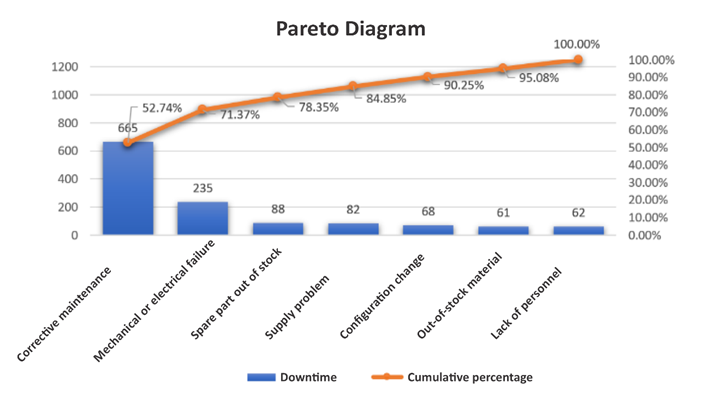

A Pareto Diagram was developed during this phase to identify key problems, prioritize actions, and focus on root causes, as shown in Figure 4.

Figure 4. Pareto Diagram.

Source: Prepared by the authors.

Figure 4 illustrates that 80% of the downtime is attributed to issues related to corrective maintenance, mechanical or electrical failure, and out-of-stock spare parts. Since corrective maintenance often arises from equipment failures, addressing these failures directly could significantly reduce downtime. Therefore, the next step was to find the main causes of electrical and mechanical failures. An FMEA was conducted for this purpose, as shown in Table 5.

Table 5. FMEA in the Weaving Process.

|

Problem |

Problem Description |

Failure Mode |

Effect |

S |

O |

D |

RPN |

|

Fabric and Weft Problems |

Problems related to the integrity and arrangement of warp and weft yarns can affect the uniformity and overall structure of the fabric. |

Variation in the edge of the fabric |

Deformation of the final product that leads to issues with adjustment in subsequent processes |

6 |

7 |

8 |

336 |

|

Threads protruding at the edges |

Poor appearance and strength of the product that also causes problems in the subsequent stage |

7 |

6 |

4 |

168 |

||

|

Short wefts missing on the entry or take-up side |

Discontinuities in the fabric that affect its uniformity |

6 |

5 |

5 |

150 |

||

|

Lighter areas on the fabric in the weft direction |

Weaknesses and variations in the fabric that reduce its quality |

6 |

9 |

5 |

270 |

||

|

Overlapping and alternating of the weft yarn |

Incorrect pattern and irregular weave structure |

5 |

4 |

4 |

80 |

||

|

Yarn Breakage and Defects |

Problems related to frequent yarn breakage and loose ends can compromise fabric quality and lead to interruptions in production. |

Loose ends of yarn at the edges and bottom |

Tangling in machinery that leads to quality reduction |

6 |

5 |

3 |

90 |

|

Frequent stoppages due to lack of weft |

Production delays |

7 |

9 |

3 |

189 |

||

|

Frequent yarn breakage at the edges |

Defective products and loss of material |

7 |

7 |

3 |

147 |

||

|

Frequent yarn breakage on the front side |

Interruptions in the process |

7 |

7 |

3 |

168 |

||

|

Frequent yarn stoppages in the harness assembly and at the rear of the shed |

Delays and issues in quality fabric production |

7 |

5 |

3 |

105 |

||

|

Loom Structure |

Problems related to the physical structure of the loom and how this affects the shape and homogeneity of the fabric. |

Torn fabric |

Destruction of fabric being woven |

9 |

8 |

5 |

360 |

|

Fabric detachment from the supports |

Generation of unusable products and delays |

7 |

5 |

4 |

140 |

||

|

Visible support marks |

Poor appearance and quality of the fabric |

6 |

8 |

3 |

144 |

||

|

Excessively wide edges |

Products out of specification |

6 |

5 |

2 |

60 |

||

|

Weft insertion defect during transferring |

Issues with the pattern and structure of the fabric |

6 |

5 |

2 |

60 |

||

|

Mechanisms and Components of the Loom |

Problems related to the internal mechanisms of the loom, including components that may influence the proper operation of the equipment. |

Threads protruding at the edges of the take-up mechanism |

Tangling and damage to machinery |

7 |

7 |

3 |

147 |

|

The shuttle system does not stop the machine |

Operator safety risks and potential damage to machinery |

9 |

7 |

4 |

252 |

||

|

The machine stops for no apparent reason |

Delays in production and loss of efficiency |

7 |

7 |

2 |

98 |

Source: Prepared by the authors.

Thus, the main problems were identified and summarized in Table 6 based on the RPN score assigned.

Table 6. Main Problems in the Weaving Department.

|

Code |

Problem |

RPN |

|

P1 |

Torn fabric |

360 |

|

P2 |

Variation in the edge of the fabric |

336 |

|

P3 |

Lighter areas on the fabric in the weft direction |

270 |

|

P4 |

The shuttle system does not stop the machine |

252 |

|

P5 |

Frequent stoppages due to lack of weft |

189 |

|

P6 |

Threads protruding at the edges |

168 |

|

P7 |

Frequent yarn breakage at the front of the loom during the shed formation process |

168 |

|

P8 |

Short wefts missing on the entry or take-up side |

150 |

|

P9 |

Frequent yarn breakage at the edges |

147 |

Source: Prepared by the authors.

Subsequently, a causality matrix was created to identify causes and subcauses contributing to these problems. The resulting matrix is displayed in Table 7.